High-Efficiency Steel Wire Rope Coiling and Cutting Machine - Automate Your Wire Rope Handling

Introduction:

Introducing the Steel wire rope coiling and cutting machine, a versatile and robust solution designed to revolutionize your steel wire rope processing. This advanced machine excels at performing multiple functions, including precision coiling, accurate cutting with statistical length measurement, and secure tying – delivering a complete Coiled Cut Tied solution. Equipped with both cable bundling and meter counting function, as well as wire coil winding and binding capabilities, this machine streamlines your workflow and enhances productivity. Furthermore, its adaptability extends to cable rewinding, making it an indispensable asset for comprehensive wire rope management and preparation.

Key Features for Enhanced Wire Rope Processing:

This Steel wire rope coiling and cutting machine is packed with features engineered for optimal performance and ease of use:

- Multi-Functional Operation: Seamlessly integrates steel wire rope coiling, precision cutting, and secure tying into one efficient machine, providing a complete Coiled Cut Tied solution.

- Statistical Length Measurement: Incorporates advanced statistical length measurement for accurate cutting and coil lengths, minimizing material waste and ensuring consistency.

- Integrated Cable Bundling and Meter Counting: Features built-in cable bundling and meter counting function, allowing for precise length control and efficient bundle creation.

- Versatile Wire Coil Winding and Binding: Offers robust wire coil winding and binding capabilities, creating neat and secure coils ready for packaging or further processing.

- Cable Rewinding Capability: Adaptable for cable rewinding operations, providing flexibility for handling and repurposing wire rope stock.

- Large Winding Dish Diameter: Equipped with a 350mm outer diameter winding dish, accommodating substantial coil sizes.

- High Cutting Capacity: Capable of cutting wire ropes with a diameter of <8mm, suitable for a broad range of steel wire rope sizes.

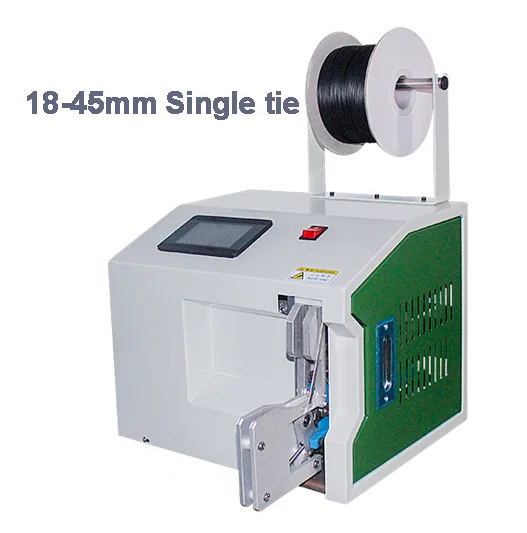

- Adjustable Tying Parameters: Features adjustable tying wire length (120-200mm) and suitable coil diameter for tying (18-45mm), allowing for customization based on coil size and material.

- High-Speed Winding: Achieves a fast winding speed of 1-10 seconds per circle, significantly boosting throughput.

- Durable and Robust Construction: Built to withstand demanding industrial environments with a weight of 230KG and sturdy dimensions.

Versatile Applications Across Industries:

This machine is ideally suited for a variety of industries handling steel wire rope, including:

- Steel Wire Rope Manufacturing: Essential for manufacturers of steel wire rope, streamlining production and ensuring quality control through accurate measurement and consistent coiling.

- Cable and Wire Distribution: Perfect for distributors and warehouses needing to rewind, measure, coil, and bundle steel wire rope for efficient storage and shipment.

- Construction and Infrastructure: Beneficial for companies using steel wire rope in construction, providing prepared and measured coils for various applications.

- Mining and Lifting Industries: Suitable for preparing steel wire rope used in mining equipment and lifting gear, ensuring safe and accurately sized lengths.

- Any Industry Using Steel Wire Rope: Adaptable for any application requiring efficient and automated handling, measuring, coiling, cutting, and tying of steel wire rope.

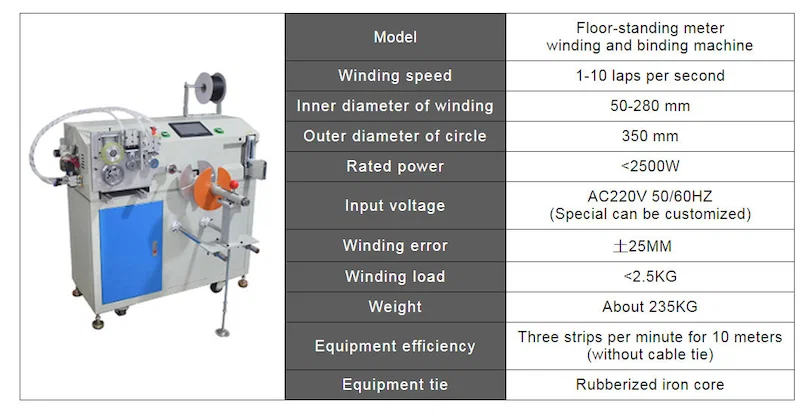

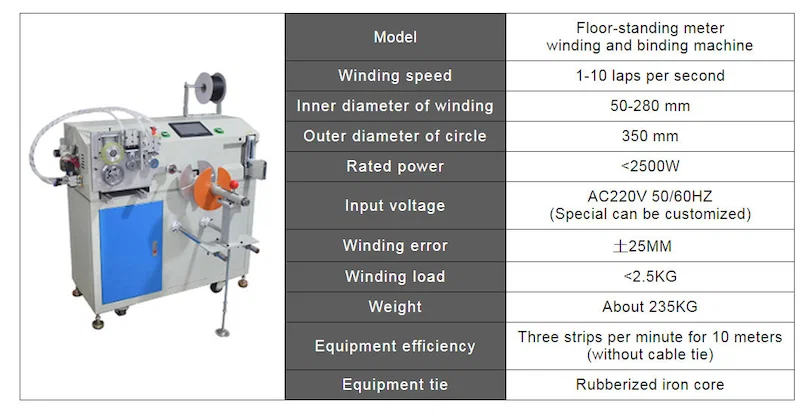

Technical Specifications for Demanding Operations:

- Machine Type: Steel Wire Rope Coiling and Cutting Machine

- Functions: Coiling, Cutting, Tying, Rewinding, Meter Counting, Bundling

- Key Features: Statistical length measurement, cable bundling and meter counting function, wire coil winding and binding capabilities, cable rewinding

- Winding Dish Outer Diameter: 350mm

- Cutting Diameter: <8mm

- Tying Wire Length: 120-200mm

- Cable Tie Material: Rubber wrapped iron wire

- Suitable Coil Diameter for Tying: 18-45mm

- Voltage: AC220V 50Hz/60Hz

- Cable Coil Diameter: 50-280mm

- Rated Power: <2500W

- Winding Speed: 1-10 sec/circle

- Weight: 230KG

- Dimensions: L1000W450H800(mm)

- Winding Tolerance: 25mm

- Loading Weight of Winding Wire: <2.5KG

- Efficiency: 3*10-meter coils of cable/min without tying

Conclusion:

Invest in the Steel wire rope coiling and cutting machine to transform your steel wire rope handling processes. This multi-functional machine, offering Coiled Cut Tied solutions with integrated cable bundling and meter counting function and wire coil winding and binding capabilities, is the ultimate solution for maximizing efficiency, accuracy, and productivity in your operations. Contact us today to learn more about how this machine can revolutionize your workflow and enhance your output!