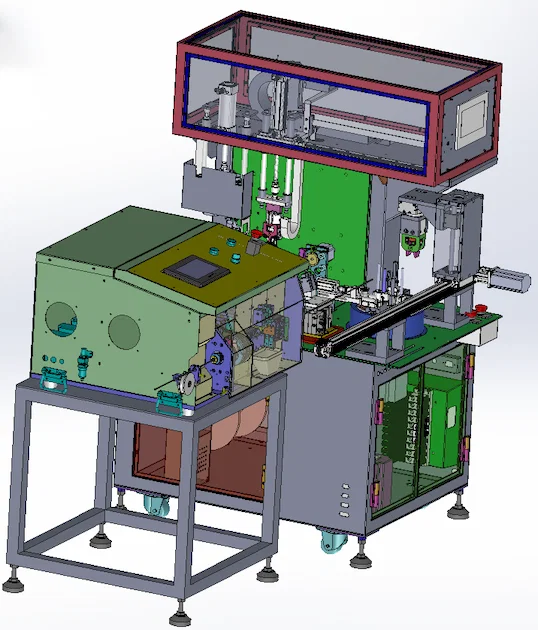

Automatic wire twisting and tying machines, automatic coiling and binding machines, as well as wire/cable bundle tying machines are all examples of automated tying equipment.

Suitable for AC/DC/USB cable

Winding appearance large 8-word single-tie tape

Applicable line length ≤10 m

Applicable wire diameter ≤ φ 12 mm

The spacing of winding is 150-300mm

Binding diameter ≤45 mm

The head length is 0-130 mm

Tail length >0 mm

Production efficiency 1000PCS /h (1-meter line length, 3 turns, outcrop, and tail)

Applicable pressure 0.55-0.65Mpa

Applicable tie tape ≤7.5 KG/ roll

Applicable voltage 220V 50Hz

Machine power ≤2800W