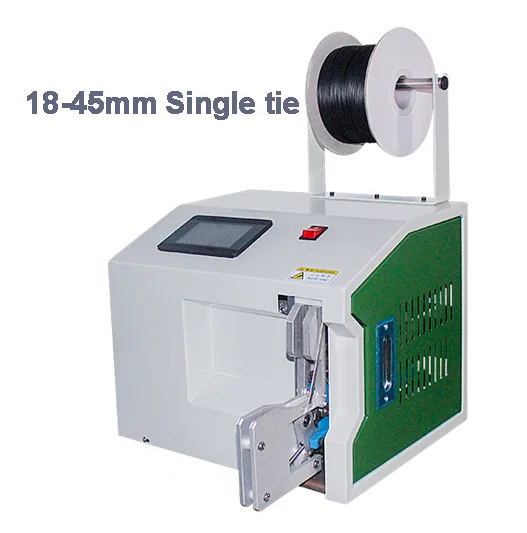

Coiling binding machine for socket WPM-210

Automatic Coiling Binding Machine for Sockets WPM-210 - Streamline Your Cable Bundling Process

Introduction:

Introducing the Coiling binding machine for socket WPM-210, a highly efficient and automated solution designed to optimize your cable bundling operations. This advanced Coiling binding machine is specifically engineered for socket cables, AC power cords, DC power cords, USB cables, and various other transmission lines. The WPM-210 utilizes encapsulated core twist ties to create neat and secure bundles, and it can also be adapted for tape and other sealing plastic bag cores, offering exceptional versatility. This machine is your key to reducing employee fatigue, dramatically improving work efficiency, and saving on cable tie material costs.

Key Features for Enhanced Cable Bundling:

The Coiling binding machine for socket WPM-210 is packed with features designed for superior performance and ease of use:

- Versatile Cable Compatibility: This Coiling binding machine is expertly designed to handle a wide range of cable types, including AC power cords, DC power cords, USB cables, sheathed cables, shielded cables, video cables, and HDMI high-definition cables, ensuring broad applicability across diverse product lines.

- Automatic Winding and Tying Operation: Employees simply place the wires onto the designated port, and the machine automatically performs the winding operation. Then, placing the wound wires at the tying port initiates automatic tying, significantly reducing manual steps and increasing throughput.

- Fatigue Reduction and Efficiency Improvement: Automating the coiling and binding process with the WPM-210 dramatically reduces employee fatigue strength, allowing for sustained productivity and improving overall work efficiency within your production line.

- Cable Tie and Material Savings: Optimize material usage with the WPM-210, designed to save on cable ties compared to manual methods, contributing to cost-effectiveness and resource conservation.

- Customizable Binding Parameters: The machine allows users to set the binding wire length and the number of laps per tie, providing flexibility to tailor the binding process to specific cable types and desired bundle tightness.

- Yield Counting Functionality: Integrated yield counting feature provides accurate tracking of production output, enabling better monitoring and management of production volumes.

- PLC Program Control with Text Display: Employs a user-friendly PLC control program and text display interface for parameter setting, making operation straightforward and easy to learn, minimizing training time.

- Adjustable Spacing and Replaceable Fixtures: Designed for versatility, the WPM-210 features easily adjustable spacing and replaceable fixtures, accommodating both "8"-shaped and round tying styles, and a large range of bundle sizes, maximizing its adaptability to different product needs.

Wide Range of Applications Across Industries:

This Coiling binding machine is ideally suited for various industries that manufacture or process cables and wires, including:

- Electronics Manufacturing: Essential for bundling cables in electronic devices, components, and assemblies, improving organization and production speed.

- Computer and Peripheral Production: Perfect for manufacturing computers and peripherals that require neatly bundled and tied cables for internal wiring and external connections.

- Appliance Manufacturing: Ideal for organizing power cords and internal wiring harnesses in household and commercial appliances, ensuring neat and secure cable management.

- Telecommunications Equipment Production: Suitable for bundling cables used in telecommunications equipment, contributing to organized and reliable wiring systems.

- Automotive Wiring Harness Assembly: Adaptable for certain automotive wiring harness applications requiring coiling and binding of wires and cables.

- Any Manufacturing Using Bundled Cables: Applicable across diverse industries where efficient and consistent coiling and binding of various types of cables and wires are required.

Technical Specifications for Reliable Performance:

- Model: WPM-210

- Machine Type: Automatic Coiling and Binding Machine

- Suitable Cable Types: AC power cords, DC power cords, USB cables, sheathed cables, shielded cables, video cables, HDMI high-definition cables, etc.

- Core Type Compatibility: Encapsulated core twist ties, tape and other sealing plastic bag cores

- Operation: Automatic winding and tying

- Control System: PLC Program Control

- Interface: Text Display for Parameter Setting

- Adjustability: Binding wire length, number of laps, spacing, replaceable fixtures (for "8" shape and round tying)

- Functionality: Yield Counting

Conclusion:

Invest in the Coiling binding machine for socket WPM-210 to revolutionize your cable bundling operations. This efficient and versatile machine automates key processes, reduces labor costs, and improves product quality, making it the ultimate Coiling binding machine for maximizing your production efficiency and cable management. Contact us today to learn more about how the WPM-210 can transform your production line and elevate your manufacturing capabilities!

This machine is suitable for AC power cords, DC power cords, USB cables, sheathed cables, shielded cables, video cables, HDMI high-definition cables, and other types of transmission lines using encapsulated core twist-tied into a bundle, can also be used to tape and other sealing plastic bag cores. This machine can reduce employee fatigue strength, improve work efficiency, save cable ties, and so on. Employees simply put the wires on the port it will automatically wind, then putting these wires around the Norse mouth, the machine will automatically Norse. The machine can set the binding wire length and number of laps, and count the yield. The machine adopts a PLC control program, and text display for parameter setting, easy to operate. Adjusting spacing, and replacement of fixtures is very convenient, ("8" -shaped tying, tying round universal, large range of bundled, widely used.)

Parameters:

| 1 | Power supply | AC220V AC110V |

| 2 | Power frequency | 50HZ/60HZ |

| 3 | Rated power | 120W |

| 4 | Winding length | Adjustable |

| 5 | Winding laps | Adjustable |

| 6 | Winding speed | Adjustable |

| 7 | Scope of application | Norse length | Norse diameter range |

| 65-120mm | Φ4—Φ18mm |

| 80-140mm | Φ8—Φ28mm |

| 115-180mm | Φ18—Φ40mm |

| | | 140-220mm | Φ28—Φ50mm |

| 8 | Norse laps | Can be set (recommended 3-6 laps) |

| 9 | cable ties | Packet core cable ties, cable ties of coreless |

| 10 | protective device | Fuses, fault alarm shutdown |

| 11 | Size(LXWXH) | 400x380x580mm |

| 12 | Total weight | 40-72Kg |