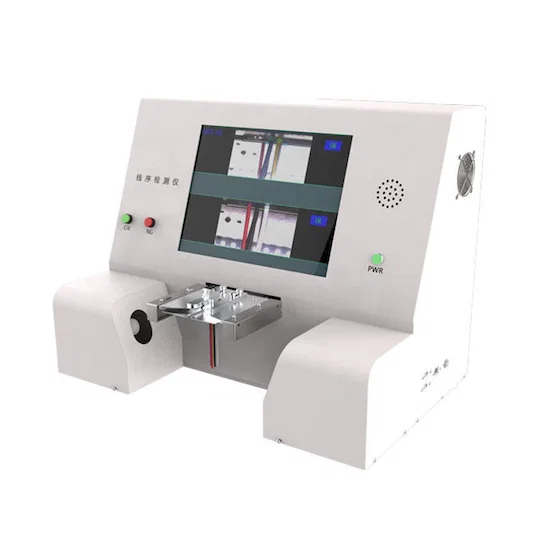

WPM-8683 Power Cord Cable Harness Tester | Wiring Harness Test Machine | Comprehensive Power Cord Plug Cable Testing

Introduction:

Ensure the safety and compliance of your power cords and cable harnesses with the WPM-8683 Power Cord Cable Harness Tester. This advanced Wiring Harness Test Machine is specifically engineered for rigorous testing of power cords, plug

cables, and wiring harnesses, guaranteeing adherence to international

safety standards. Designed to meet and exceed requirements from UL,

VDE, CSA, SAA, T-MARK, KS, IRAM, CCC, and more, the WPM-8683 is your

ultimate solution for verifying the integrity and reliability of your

power cord products. Whether you are testing single-end, double-end, or

three-end power supply cords, this Wiring Harness Connection Testing Machine provides automated, comprehensive testing to safeguard your production and meet global regulatory demands.

Key Features and Benefits:

-

Compliance with International Standards: Designed to meet stringent standards including UL, VDE, CSA, SAA,

T-MARK, KS, IRAM, and CCC, ensuring your products are compliant for

global markets.

-

Versatile Power Cord Testing: Capable of testing single-end, double-end, and three-end power supply cords, offering broad application coverage.

-

Automated Comprehensive Testing Suite: Performs automatic and continuous testing for Continuity (COND),

Insulation Resistance, Leakage Current, Line-to-line Hi-pot (internal

HV), Leaking copper (external HV), and Relative Length, covering all

critical safety and performance parameters.

-

Automated Defect Handling: Automatically identifies and handles defective products. Qualified

products can be ejected and marked, while defective products are

automatically cut, alarmed with audio and visual signals, and locked for

segregation.

-

PC Communication and Upgradeability: Equipped with RS 232 interfaces for seamless communication with a PC,

facilitating data logging, remote control, and easy software upgrades

for future needs.

-

Customizable Solutions: Offers personalized customization options to cater to specific testing requirements and unique production line integrations.

-

Polarity and Connection Fault Detection: Detects polarity issues including break overs, short circuits, open

circuits, and dislocations, ensuring correct wiring configuration.

-

Adjustable Leakage Current Settings: Offers selectable Leakage Current Setting Ranges (0.5, 1.0, 2.0, 3.0,

5.0, 10mA) for precise testing based on product specifications and

standards.

-

Dual High-Voltage Output (Internal & External): Features both Internal and External High-Voltage Outputs adjustable

from 0-5KV (500VA), providing flexibility for various Hi-pot testing

scenarios.

-

Precise Insulation Resistance Testing: Offers selectable Insulation Resistance Ranges (2, 7, 20, 50, 100, 200

MΩ) with 0.5 level resolution, ensuring accurate insulation quality

assessment.

-

Adjustable Voltage Withstand Time: Allows setting Voltage Withstand Time ranging from 0.1 to 99.9 seconds, accommodating different test duration requirements.

-

Rapid Testing Cycle: Achieves a minimum item measuring time of just 0.3 seconds, maximizing

throughput and efficiency in high-volume production environments.

-

High Wire Sensitivity: Boasts a wire sensitivity of >10pF, ensuring detection of even subtle wiring issues.

-

Clear OK/NG Product Indication: Provides clear visual and auditory feedback. OK products are indicated

with automatic printing, ejection, counting, and an indicator light. NG

products trigger automatic locking, counting, indicator light, and a

buzzer alarm.

-

Comprehensive Safety Safeguards: Equipped with safeguards against electric leakage, short circuits, and

overheating, ensuring operator safety and protecting the equipment

during operation.

Detailed Features and Specifications (Expanding on Key Points):

The WPM-8683 Power Cord Plug Cable Tester is designed for rigorous and automated testing of power cords and

wiring harnesses. Its core function is to ensure that power cords meet

stringent international safety and performance standards. The tester is

pre-programmed to conduct a sequence of critical tests including

Continuity (COND), Insulation Resistance, Leakage Current, High

Potential (Hi-pot) tests both internally and externally (Line-to-line

and Leaking copper), and Relative Length verification.

The

automated testing process significantly enhances production efficiency

and reduces human error. The system automatically identifies pass/fail

criteria based on pre-set parameters and actively manages product flow.

Successfully tested cords can be automatically marked and ejected,

streamlining the production line. Conversely, failed cords are

automatically cut to prevent them from entering the supply chain, and a

clear alarm system with both visual and audible cues alerts operators to

the defective product.

The

WPM-8683 offers a high degree of customization. With RS 232

interfaces, the tester can be easily integrated into data management

systems, allowing for real-time monitoring and data logging.

Furthermore, the software and functionality can be personalized to

accommodate specific testing protocols and unique product requirements.

The

tester's robust design incorporates multiple safety features. Built-in

safeguards protect against electric leakage, short circuits, and

overheating, ensuring operator safety and the longevity of the equipment

even under heavy usage in demanding production environments.

Technical Specifications Table:

|

Product Name

|

Power Cord Cable Harness Tester

|

|

Model Number

|

WPM-8683

|

|

Usage Standards Compliance

|

UL, VDE, CSA, SAA, T-MARK, KS, IRAM, CCC, etc.

|

|

Testable Cord Types

|

Single-ends, Double-ends, Three-ends Power Cords

|

|

Automated Tests

|

COND, Insulation Resistance, Leakage Current, Line-to-line Hi-pot (Internal HV), Leaking Copper (External HV), Relative Length

|

|

Polarity Testing

|

Break over, Short Circuit, Open Circuit, Dislocation

|

|

Leakage Current Setting Range

|

0.5, 1.0, 2.0, 3.0, 5.0, 10mA

|

|

Internal High-Voltage Output

|

0-5KV (500VA) Adjustable

|

|

External High-Voltage Output

|

0-5KV (500VA) Adjustable

|

|

Operating Voltage

|

220VAC, 12A, 50/60Hz

|

|

High-Voltage Range

|

0-5KV

|

|

High-Voltage Resolution

|

0.5 Level

|

|

Insulation Resistance Output Voltage

|

DC500V

|

|

Insulation Resistance Range

|

2, 7, 20, 50, 100, 200 MΩ

|

|

Insulation Resistance Resolution

|

0.5 Level

|

|

Voltage Withstand Time Range

|

0.1-99.9 Seconds

|

|

Minimum Measuring Time

|

0.3 Seconds

|

|

Wire Sensitivity

|

>10pF

|

|

Barometric Pressure

|

<4 Kg f / cm²

|

|

OK Product Indication

|

Automatic Printing, Ejection, Counting, Indicator ON

|

|

NG Product Indication

|

Automatic Locking, Counting, Indicator ON, Buzzer Ringing, Automatic Cutting, Alarm

|

|

Communication Interface

|

RS 232

|

|

Safety Safeguards

|

Electric Leakage, Short Circuit, Overheating

|

|

Dimensions

|

730 x 530 x 500 mm

|

|

Weight

|

80 KG

|

Applications:

The WPM-8683 Power Cord Cable Harness Tester is essential for quality control in various industries, including:

-

Power Cord Manufacturing: Ensuring all power cords meet strict safety and performance standards before distribution.

-

Appliance Manufacturing: Testing power cords integrated into appliances to guarantee consumer safety.

-

Electronics Manufacturing: Verifying power cables for computers, peripherals, and other electronic devices.

-

Electrical Component Suppliers: Providing certified and reliable power cords and cable assemblies to OEM manufacturers.

-

Quality Assurance Laboratories: Performing comprehensive testing and certification of power cords and related products.

-

Cable Harness Production: Testing power wiring harnesses for various industrial and commercial applications.

Conclusion (Call to Action - Implicit):

Invest in the WPM-8683 Power Cord Cable Harness Tester to guarantee the safety, compliance, and reliability of your power

cords and wiring harnesses. Experience the benefits of automated,

comprehensive testing, enhanced production efficiency, and adherence to

international standards. Contact us today to learn more about how the

WPM-8683 can optimize your quality control process and ensure your

products meet the highest global benchmarks.