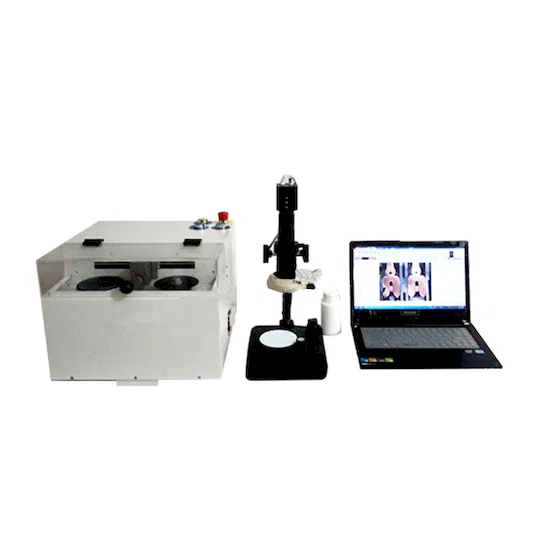

Achieve Unparalleled Precision in Wire Harness Quality Control with the WPM-SE4 Fully Automatic Terminal Cross-Section Analyzer

Introduction:

In

the demanding landscape of wire harness manufacturing, ensuring the

integrity and reliability of terminal crimps is paramount. Introducing

the WPM-SE4 Fully Automatic Terminal Cross-Section Analyzer,

a state-of-the-art precision instrument specifically engineered to

revolutionize your wire harness quality inspection process. This

comprehensive system is not just a machine; it's a complete solution,

meticulously designed to deliver rapid, accurate, and repeatable

cross-sectional analysis of wire harness terminals. From automotive to

aerospace, the WPM-SE4 empowers manufacturers across industries to

guarantee the highest standards of crimp quality, minimizing defects and

maximizing product performance.

Key Features and Benefits: Precision, Speed, and Automation Redefined

The

WPM-SE4 stands as a pinnacle of engineering excellence, integrating

cutting-edge technologies to provide unparalleled performance and user

experience. Here's a detailed breakdown of the key features that make

this analyzer an indispensable asset for your quality control

operations:

-

Fully Automatic, Integrated System for Streamlined Workflow: The WPM-SE4 is a fully automatic system, seamlessly integrating every step of the cross-section analysis process. From precision cutting and grinding to optical sampling, corrosion cleaning, and image acquisition,

everything is automated within a single, cohesive unit. This automation

drastically reduces manual intervention, minimizes operator error, and

ensures consistent, repeatable results.

-

Patented One-Step Cutting and Grinding Technology: Leveraging the latest patented technology, the WPM-SE4 performs cutting and grinding in a single, synchronized operation. This innovative approach guarantees perfect terminal flatness – a critical factor for accurate cross-sectional analysis. This

eliminates inconsistencies introduced by separate cutting and grinding

processes, providing a superior sample preparation and more reliable

data.

-

Unprecedented Speed: Complete Analysis in Just 3 Minutes: Time is critical in manufacturing. The WPM-SE4 is engineered for speed, capable of completing the entire processing and analysis of a single terminal in a remarkable 3 minutes.

This exceptional throughput dramatically accelerates your quality

inspection process, allowing for faster feedback, quicker issue

identification, and increased production efficiency.

-

Simple, Convenient, and Fast Operation for Enhanced User Experience: Despite its sophisticated technology, the WPM-SE4 is designed for simple, convenient, and fast operation. The intuitive interface and automated processes minimize training

requirements and maximize operator efficiency. Focus on results, not

complex procedures.

-

Japan-Imported High-Definition Image Acquisition System for Uncompromising Clarity: At the heart of the WPM-SE4 lies a Japan-imported high-definition image acquisition system. This advanced system captures incredibly detailed cross-sectional images, ensuring accurate measurement and analysis. The superior image quality allows for precise evaluation of crimp

characteristics, leading to more informed quality decisions. The system

boasts a 5 million pixel Japanese industrial HD video system, delivering exceptional visual clarity.

-

Japan-Imported Segment Less Zoom Optical System for Detailed Observation: The analyzer incorporates a Japan-imported segment less zoom optical system. This high-quality optics system provides a total video magnification range of 30~312X,

allowing for both overview perspectives and highly detailed examination

of crimp structures. This versatile magnification range ensures you

can analyze every aspect of the terminal cross-section with exceptional

clarity.

-

Precision Components for Unwavering Reliability and Accuracy: The WPM-SE4 is built with premium components for long-lasting performance and exceptional accuracy:

-

German Motor: Ensures powerful and reliable operation of the cutting and grinding mechanisms.

-

Japanese Panasonic Servo Motors (X & Y Axis): Provide precise and controlled movement for both X and Y axes during

the cutting and grinding process, guaranteeing accuracy and

repeatability.

-

Japanese Mitsubishi PLC Controller: Acts as the intelligent brain of the system, ensuring smooth and coordinated operation of all automated processes.

-

Comprehensive Terminal Section Analysis Software (Japan-Imported): The WPM-SE4 is equipped with professional terminal section analysis software imported from Japan. This software is specifically designed for analyzing crimp

cross-sections, providing a range of measurement and analysis tools to

quantify crimp quality. For data security and software integrity, the

software is equipped with an encryption lock and provided on CD.

-

Wide Applicable Wire Range for Versatile Testing: The WPM-SE4 is designed to handle a broad spectrum of wire sizes, with an applicable wire range of 0.01~50mm2. This versatility ensures the analyzer can accommodate a wide variety

of wire harness applications, from delicate signal wires to larger power

cables.

-

Durable and Delicate German-Imported Blade: The cutting process utilizes a Dia.110X0.5mm blade imported from Germany. This blade is renowned for its delicate yet durable nature, ensuring clean and precise cuts while maintaining long-term sharpness and reliability.

-

Precise Corrosion Cleaning for Optimal Image Clarity: The system incorporates a terminal corrosion liquid cleaning process, completed in just 5 seconds.

This rapid cleaning step removes debris and contaminants from the

cross-section, ensuring optimal image clarity for accurate analysis.

-

Adjustable LED Lighting for Consistent Illumination: An all-white adjustable LED lighting device provides consistent and controlled illumination of the terminal

cross-section. This adjustable lighting ensures optimal visibility and

image quality, regardless of terminal material or ambient lighting

conditions.

-

Compact Footprint for Easy Integration into Workspaces: With dimensions of W500XD350XH350, the WPM-SE4 boasts a compact footprint, making it easy to integrate into existing laboratory or production floor workspaces.

Technical Specifications:

| Model | WPM-SE4 |

| Terminal Section Analysis System | Japan imported segment less zoom optical system |

| Total Video Magnification | 30~312X |

| Applicable Wire Range | 0.01~50mm2 |

| Power Supply | 100~240VAC, 50/60Hz |

| Imaging System | Japanese industrial HD video system 5 million |

| Blade Specifications | Dia.110X0.5mm (Germany imported, delicate and durable) |

| Abrasive Sandpaper | 1200# |

| Standard Fixture | 0.01~50mm2 |

| Reference Ruler | Special-grade high-precision 0.01/10mm |

| Terminal Corrosion | Liquid cleaning (5S completed) |

| Lighting Source | All white adjustable LED lighting device |

| Dimensions (W x D x H) | W500XD350XH350 |

Applications:

The

WPM-SE4 Fully Automatic Terminal Cross-Section Analyzer is essential

for quality control in a wide range of industries, including:

-

Automotive Wire Harness Manufacturing: Ensuring the reliability and safety of automotive electrical systems.

-

Aerospace and Defense: Meeting stringent quality standards for critical wiring in aircraft and defense systems.

-

Consumer Electronics: Guaranteeing the long-term performance of wire terminations in electronic devices.

-

Industrial Equipment Manufacturing: Verifying the robustness of wiring in machinery and control systems.

-

Medical Device Manufacturing: Maintaining the highest levels of quality for wiring in life-critical medical equipment.

-

Telecommunications: Ensuring reliable connections in communication infrastructure.

Conclusion:

The WPM-SE4 Fully Automatic Terminal Cross-Section Analyzer is not just equipment; it's an investment in quality, efficiency, and

customer satisfaction. By providing rapid, precise, and automated

terminal cross-section analysis, the WPM-SE4 empowers you to elevate

your wire harness quality control processes, minimize defects, and

deliver consistently reliable products. Contact us today to learn how

the WPM-SE4 can transform your quality inspection and drive your

business forward.