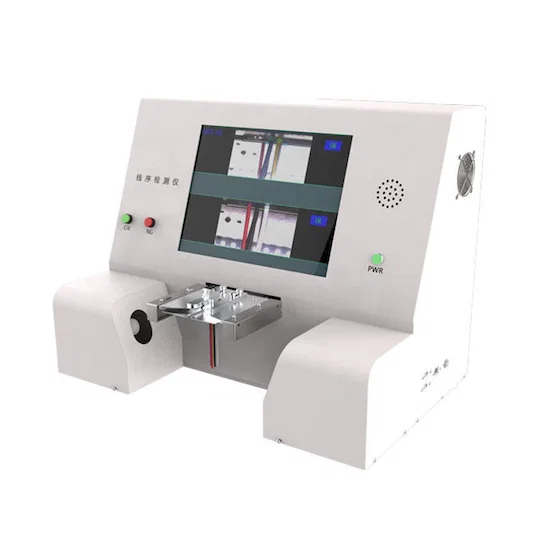

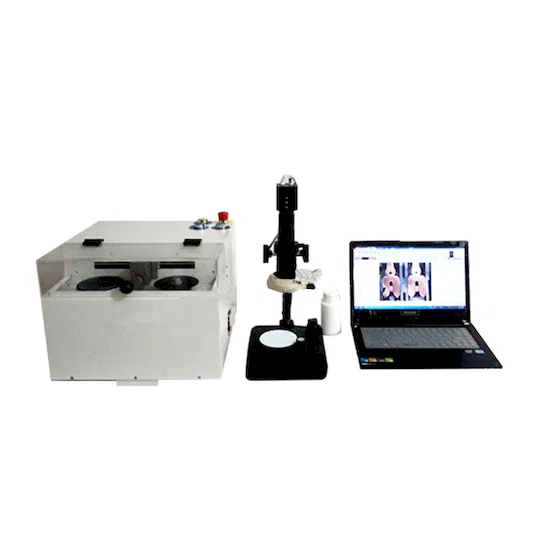

Double Row Housing Wires Sequence Test Machine, Double Row Wires Sequence Test Machine, Double Row Wires Sequence Inspection Machine

Voltage 200-240VAC 50/60HZ

Weight 20kg

Packing size 560*440*450mm

Working environment Temp 0-40°C, Relative humidity

Color test Wire sequence color misordering, misplacement, wrong PIN

Continuity test 64PIN continuity/open circuit/Instantaneous open test

Test result voice broadcast, NG lock

Applicable products Automotive wire harness, single end 2-row, 2-ends 2-row, Type-C, HDM1, USB, wire-to-PCB, customized

2-row wire harness color and continuity tester

There are a series of wire harness sequence testers:

Single function, Single row / 2-row, wire sequence test;

2-in-1, Single row / 2-row, wire sequence & continuity test;

3-in-1, Single row / 2-row, wire sequence & continuity & point print;

Multi-end housing composite wire harness test.

And so on.