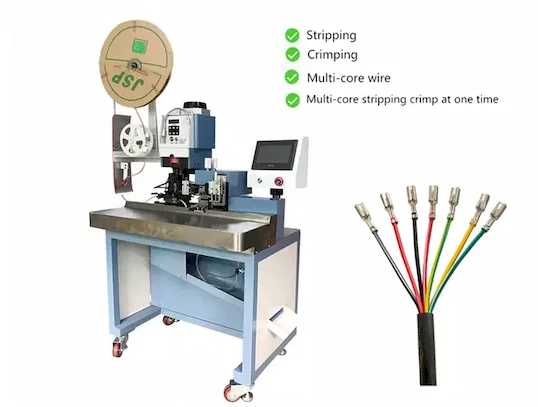

Loose Tubular Terminal Crimping Machine, Loose Insulator Crimping Machine, Wire Strip And Crimping Machine, European Single Terminal Press Machine

Stripping length 8-12mm

Speed 1.5s/time

Control method touch screen, electronic control, pneumatic control

Applicable wire BVR hard wire: 0.5-4mm2,

The soft wire needs to be twisted: 0.5-2.5 mm2

Terminal supply vibration plate feeding

Crimping method left and right horizontal crimping in parallel

Rated power supply AC220V 50Hz

Working pressure 0.3-0.8MPA

Working temperature -10/40℃

Weight about 30KG

Dimension 42cmx40cmx39cm