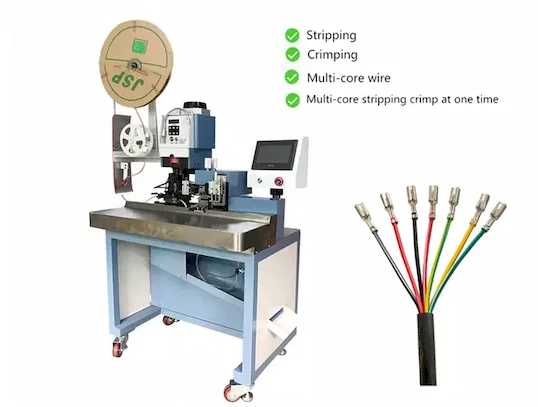

stripping crimping terminal machine

Achieve Seamless Wire Processing with the High-Precision Wire Stripping Crimping Machine

Introducing the Wire Stripping Crimping Machine, a highly efficient and precise solution for your wire processing needs. This advanced Stripping and Crimping Terminal Machine, specifically the End-feed Wire Stripping and Crimping Terminal Machine (Model: WPM-2008A2-E), streamlines wire preparation by integrating stripping and crimping into a single, coherent operation. Maximize your production throughput, enhance accuracy, and minimize noise with this cutting-edge equipment.

Integrated Operations for Unmatched Efficiency and Precision

The End-feed Wire Stripping and Crimping Terminal Machine WPM-2008A2-E is engineered for seamless wire processing. Its innovative design combines wire stripping and terminal crimping within a one-time cassette mold holder and skinning system. This integrated approach ensures a coherent motion throughout the machine's operation, resulting in faster cycle times and reduced material handling.

Unwavering Accuracy and Stability

Precision is paramount in wire processing, and the WPM-2008A2-E excels in this area. Built with the assembly of high-precision parts and featuring a meticulous adjustment method using tuning screws, this machine delivers exceptional accuracy. Experience crimping and stripping precision down to 0.05 - 0.1 mm, ensuring consistent and reliable wire terminations every time.

Quiet, Energy-Saving, and Reliable Performance

Operate in a comfortable and efficient workspace. This Wire Stripping Crimping Machine is equipped with Japanese SMC pneumatic components, known for their energy conservation and remarkably noise-free operation. The electrical system further emphasizes efficiency and reliability by adopting high-quality components that are both energy-saving and stable, contributing to long-term, dependable performance.

Key Features and Benefits of the Wire Stripping Crimping Machine WPM-2008A2-E:

- Integrated Stripping and Crimping: Combines operations for increased efficiency and reduced cycle times.

- One-Time Cassette Mold Holder: Ensures coherent and streamlined machine motion.

- High-Precision Construction: Assembled with high-precision parts for exceptional accuracy.

- Tuning Screw Adjustment: Enables meticulous precision adjustments.

- Japanese SMC Pneumatic Components: Energy-saving and noise-free operation for a comfortable workspace.

- Energy-Saving Electrical System: High-quality, stable, and energy-efficient electrical components.

- End-Feed Design: Facilitates efficient wire feeding.

- Wide Wire Capacity: Handles wire sizes from AWG#18 to 36#.

- High Production Capacity: Achieves a production capacity of 3000 - 3500 pieces per hour.

- Adjustable Stripping Length: Stripping length adjustable from 1.0 to 10.0 mm.

Technical Specifications: End-feed Wire Stripping and Crimping Terminal Machine (WPM-2008A2-E)

PRODUCTION CAPACITY 3000-3500pcs/h