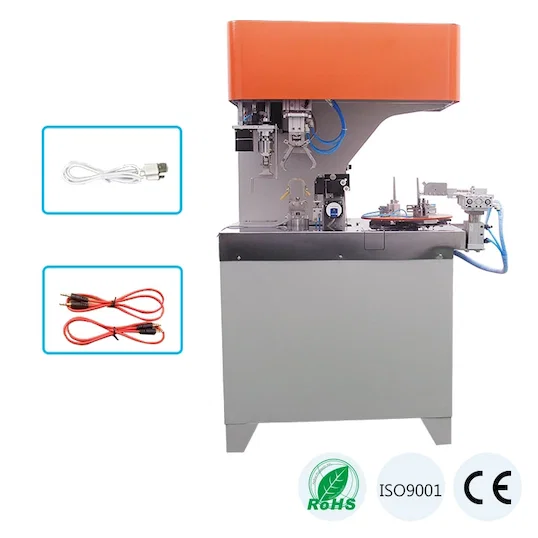

Main Components:

-

Cylinder: Yadeke cylinder and solenoid valve

-

Winding Servo Motor: 1500W Turbot

-

Line Translation Servo Motor: 750W Turbot

-

Motor: 57 stepper motor Thunder Race

-

Twisted Tie Belt Motor: 57 stepper motor Thunder Race

-

Storage Tie Belt Motor: 6W fixed speed

-

Take Line Translation: Double slider

-

Lower Jaw Translation: Double guide rail

-

PLC: Vigor

-

Screen: Dimension control

-

Power Supply: Clear Weft

-

Frame: Iron frame, painted, blue and white

-

Wire Grab/Twisting Claw/Lower Claw Material: Stainless steel

-

Drive System: High-reliability servo system with a high-speed stable industrial controller and system software (Chinese and English bilingual version).

Ideal for Streamlining Cable Management:

The WPM-RT-02T is the perfect solution for manufacturers looking to automate the winding and tying of various cables, hoses, and ropes into neat and organized coils with the flexibility of single or double ties. Its robust design and user-friendly features ensure efficient and reliable operation.

Enhance Your Production Efficiency and Product Presentation:

Invest in the WPM-RT-02T to significantly increase your production efficiency, reduce labor costs, and achieve consistently high-quality coiled and tied products. Its new design and enhanced features make it a top choice for modern manufacturing environments.

Contact us today for a quote and to learn more about how the WPM-RT-02T can optimize your cable winding and tying processes!

Keywords for Google Search: Automatic winding and tie machine, large circle winding machine, double tie machine, AC cable winding machine, DC cable winding machine, USB cable winding machine, hose winding machine, rope winding machine, WPM-RT-02T, automatic cable bundling machine, high-speed cable tying machine, servo motor cable winder, wire harness assembly equipment.