High-Speed Full Automatic Wire Winding and Tying Machine WPM-81 - Maximize Your Cable Bundling Efficiency

Introduction:

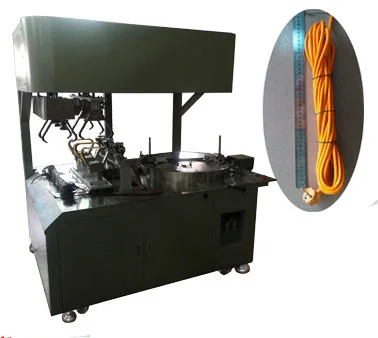

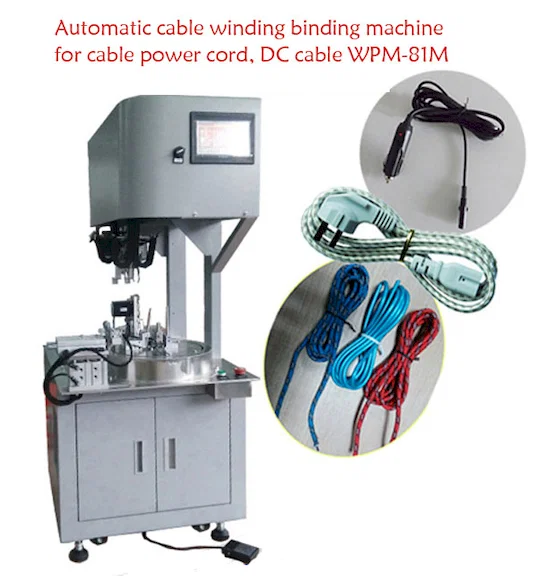

Introducing the Full automatic wire winding and tying machine WPM-81, a cutting-edge solution designed to automate and dramatically improve your cable bundling process. This advanced Wire Winding Tying Machine is engineered for speed, precision, and reliability, offering full automation of wire coiling and tying tasks. Also known as a wire twisting tie machine and automatic string tying machine, the WPM-81 significantly increases production output while maintaining consistent, high-quality cable bundles. If you're looking for a robust and efficient wire winding tying machine, the WPM-81 is the ideal choice to optimize your cable management operations.

Key Features for Unmatched Productivity:

The Full automatic wire winding and tying machine WPM-81 is packed with features designed to enhance efficiency and ease of use:

- Fully Automated Operation: Experience seamless automation with fully automatic wire winding and tying functions, significantly reducing manual labor and maximizing production throughput.

- Versatile Winding Shapes: Produces finished products in "8" shapes with a secure single tie, providing neat and organized cable bundles for professional presentation.

- Broad Cable Compatibility: Handles various wire and cable types, including AC, DC, USB, and more, offering exceptional versatility for different cable applications.

- Generous Wire Diameter Capacity: Accommodates wires and cables with outer diameters up to ≤ 6.2 mm, suitable for a wide range of cable gauges.

- Adjustable Winding Parameters: Offers adjustable winding part distance (70-200 mm) and winding length (up to ≤ 6m), allowing for customized coil sizes tailored to your specific product requirements.

- Variable Winding Speed Control: Features adjustable winding speed, optimizing the coiling process for different materials and desired coil tightness, ensuring consistent quality and efficient operation.

- Large Tying Diameter: Capable of tying coils with an outer diameter up to ≤ 55 mm, accommodating a variety of coil sizes for different cable lengths.

- Adjustable Wire Head and Tail Lengths: Offers adjustable wire head length (0-130 mm) and fixed wire tail length (> 0 mm) for precise cable end management and professional finishes.

- High-Speed Production Capacity: Achieves an impressive productivity rate of 1800 pieces per hour (for 1m winding length and 3 turns), dramatically increasing your production volume.

Wide Applications Across Diverse Industries:

This Wire Winding Tying Machine is perfectly suited for a multitude of industries, including:

- Manufacturing of AC/DC Power Cables: Ideal for high-volume production of power cables for various appliances, electronics, and industrial equipment, increasing efficiency and output.

- USB Cable Manufacturing: Streamlines and accelerates the manufacturing of USB cables, ensuring consistently coiled and tied cables ready for packaging and distribution.

- Wire Harness Assembly: Enhances efficiency in wire harness production by automating the coiling and tying of wires and cables within harnesses, improving consistency and reducing labor costs.

- Cable Assembly for Consumer Electronics: Suitable for any consumer electronics manufacturing that requires organized and neatly coiled cables and wires for product packaging and user convenience.

- General Cable Management Solutions: Adaptable to a broad spectrum of industries beyond electronics, wherever automated cable coiling and tying is essential for efficient cable handling and organization in production or packaging processes.

Technical Specifications for High-Throughput Operations:

- Model: WPM-81

- Machine Type: Full Automatic Wire Winding and Tying Machine

- Key Functions: Wire Winding Tying Machine, wire twisting tie machine, automatic string tying machine

- Finished Product Shape: 8 shapes, single tying

- Suitable Wire/Cable Type: AC / DC / USB etc.

- Wire Outer Diameter: ≤ 6.2 mm

- Winding Part Distance: 70 - 200 mm

- Winding Length: ≤ 6 m

- Winding Speed: Adjustable

- Tying Outer Diameter: ≤ 55 mm

- Wirehead Length: 0 - 130 mm

- Wire tail length: > 0 mm

- Productivity: 1800 pcs./h (winding length = 1 m, number of turns = 3)

- Compressed air connection: 0.55 - 0.65 MPa

- Power supply: 110, 220 V (50 - 60 Hz)

- Power: 2 kW

- Dimension: 1040 * 720 * 1540 mm

- Weight: 160 kg

Conclusion:

Invest in the Full automatic wire winding and tying machine WPM-81 to revolutionize your cable bundling operations. This superior automatic string tying machine and versatile wire twisting tie machine, is the ultimate Wire Winding Tying Machine solution for maximizing your production efficiency and product quality. Contact us today to learn more about how the WPM-81 can transform your production line and enhance your manufacturing capabilities!