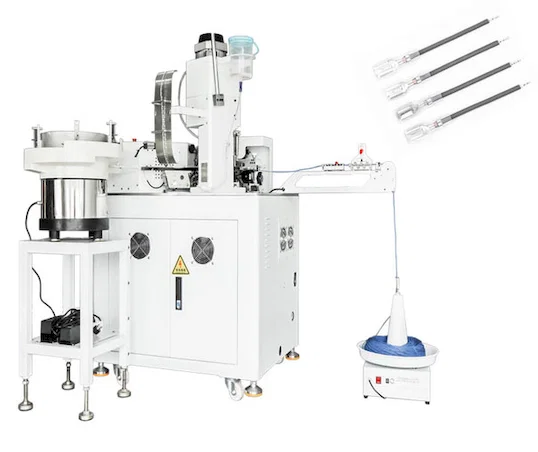

Unleash Efficiency with the Advanced Wire Cut Strip Machine: Automation for Cutting, Stripping, Crimping, and Tinning

Maximize your wire processing capabilities with the Wire Cut Strip Machine, a fully automated, high-performance solution designed to streamline your production workflow. This cutting-edge machine seamlessly integrates multiple essential processes – Wire Cut Strip, crimping, and tinning – into a single, efficient unit. The Wire Cut Strip Machine automates wire cutting, stripping, tinning on one end, and crimping on the other, delivering unmatched speed, precision, and versatility for a wide range of applications. Eliminate manual labor, boost production output, and ensure consistent quality with this innovative equipment.

Beyond basic wire preparation, the Wire Cut Strip Machine is engineered for advanced functionalities and superior performance, making it a vital asset for modern wire harness manufacturing.

Key Features and Benefits of the Wire Cut Strip Machine:

1. Fully Automatic Multi-Process Integration for Unmatched Efficiency:

Experience true automation with the Wire Cut Strip Machine. This advanced system automatically adjusts and executes a sequence of critical actions: wire cutting, precise stripping, consistent tinning on one end, and reliable crimping on the other. This comprehensive integration of Wire Cut Strip and subsequent processes significantly enhances operational efficiency, reduces manual handling, and accelerates your production cycle.

2. Broad Wire Gauge Compatibility for Diverse Applications:

Adapt to various project requirements with the machine's wide wire gauge range, accommodating wires from AWG #32 to AWG #18. This extensive compatibility makes the Wire Cut Strip Machine highly practical and suitable for diverse applications across industries, from delicate electronics to more robust wiring assemblies.

3. Twisting Functionality for Enhanced Wire Termination:

Expand your processing capabilities with the integrated twisting function. This added versatility of the Wire Cut Strip Machine allows for enhanced wire termination and preparation for specific connector types, providing greater flexibility in your wire harness production.

4. Handles Ultra-Short Wires with Precision:

Tackle even the most challenging wire processing tasks. The Wire Cut Strip Machine excels at handling ultra-short wires, processing lines as short as 18mm with middle glue remaining. This capability opens up new possibilities for intricate and compact wiring designs, demonstrating the superior engineering of this Wire Cut Strip solution.

5. Superior Tinning Quality with 90-Degree Tin Angle:

Achieve consistently high-quality tinning for reliable connections. The Wire Cut Strip Machine ensures a tin angle close to 90 degrees, resulting in even distribution of tin across the wire diameter. This precise tinning process enhances conductivity and creates more robust and dependable electrical connections.

6. Dispersion Control for Accurate Spot Depth Adjustment:

Optimize your spot welding or soldering processes with precise depth control. The Wire Cut Strip Machine adjusts the depth of spots using dispersion control, making the spot depth significantly more accurate. This precision is crucial for achieving optimal electrical contact and ensuring reliable long-term performance in your wire assemblies – a key benefit of advanced Wire Cut Strip technology.

7. Compatible with Horizontal, Straight OTP Molds for Versatility:

Maximize tooling flexibility with the machine's compatibility with horizontal, straight OTP molds. This design allows for seamless integration with commonly used tooling and provides versatility in your crimping operations, enhancing the overall adaptability of the Wire Cut Strip Machine.

8. High-Speed Processing for Increased Productivity:

Boost your output and meet demanding production schedules. The Wire Cut Strip Machine boasts a high processing capacity, reaching approximately 3,200 wires per hour for 50mm length wires (without twisting). This impressive speed significantly increases your throughput, reducing lead times and maximizing productivity in your wire processing facility.

Technical Specifications:

- Model: WPM-501S

- Capacity: Wire length 50mm, approx. 3,200 wires/hour (no twisting)

- Applicable Wire Diameter: AWG #32 ~ AWG#18

- Processing Length: (Central section with jacket remaining) 18mm ~ 99,990mm (wire clip can be refitted to 8mm)

- Stripping Length: Front 0.1~8.0mm, Rear 0.1~18.0mm

- Cutter Depth: Maximum adjustment 3.50mm, resolution 0.01mm

- Cutting Tolerance: Modifiable

- Crimping Capacity: 2 Tons

- Detection Devices: Low air pressure, wire presence, terminal presence, abnormal stripping, abnormal crimping, abnormal ingoing wire

- Auxiliary Devices: Pre-wire feeding synchronizer, terminal waste paper rewinding device

- Power Supply: Single phase, AC180V~242V, 50/60Hz, 10A

- Compressed Air: 0.5 MPa (5kgf / cm2) clean dry air

- Dimension: 1,800W × 900D × 1,450H, approx. 400KG

Transform Your Wire Processing with the Wire Cut Strip Machine Today!

The Wire Cut Strip Machine is the intelligent investment for businesses seeking to optimize their wire processing operations. Experience unmatched efficiency, precision, and versatility in your wire cutting, stripping, crimping, and tinning applications. Contact us now to learn more about how this revolutionary machine can transform your production line and provide you with a significant competitive advantage in the market for Wire Cut Strip solutions!