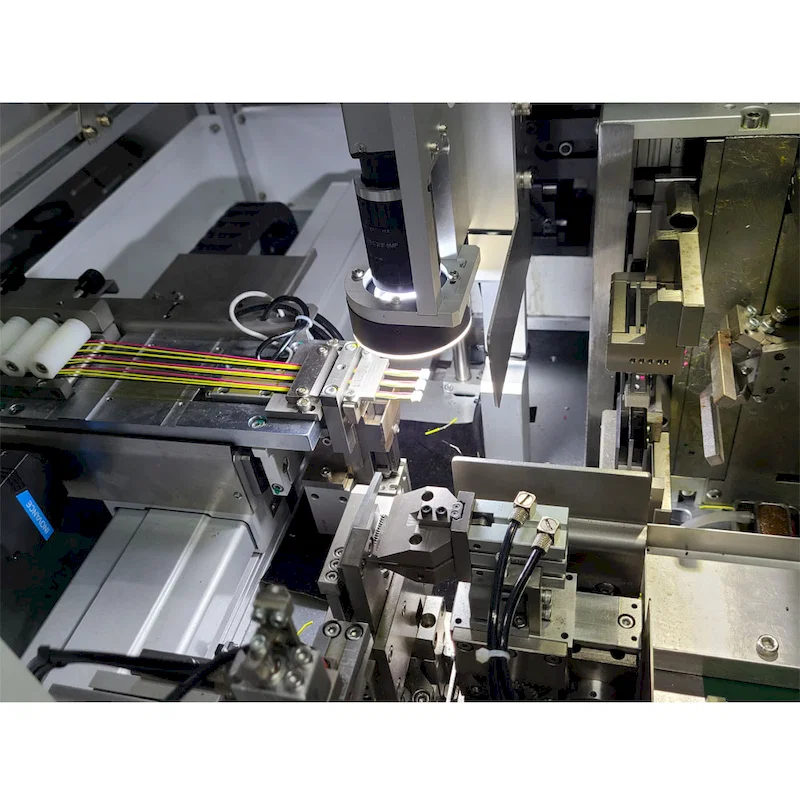

CE Certified Fully Automatic Wire Processing Machine: Crimping, Housing Insertion, Twisting & Tinning

This CE certified fully automatic wire crimping housing insertion machine is a highly advanced and efficient solution for comprehensive wire processing. This multi-functional machine seamlessly integrates automatic wire cutting, stripping, crimping, housing insertion, twisting, and tinning into a single, high-speed operation. Backed by CE certification, it ensures compliance with European safety and quality standards.

Key Features and Advantages:

-

CE Certified: Guarantees compliance with European safety and quality regulations.

-

Fully Automatic Operation: Automates the entire wire processing sequence for maximum efficiency.

-

Multi-Functional Capabilities: Integrates cutting, stripping, crimping, housing insertion, twisting, and tinning.

-

High Capacity: Processes multiple cables simultaneously, achieving high production rates.

-

Precise and Consistent Processing: Ensures accurate and reliable results for every wire.

-

Integrated Inspection Functions: Detects common processing errors, ensuring high-quality output.

-

Optional CCD Monitor & Crimping Force Monitor (CFM): Offers enhanced quality control capabilities.

-

Customizable Functions: Allows for flexible configuration to meet specific processing requirements.

-

Advanced PLC Control System: Enables digital parameter setting, file management, and remote monitoring.

-

Modular Hardware Design: Simplifies maintenance and material changes.

-

Remote Control & Monitoring: Allows for real-time production status monitoring and data export.

Detailed Functionality:

This single-end automatic crimping housing insertion tinning machine performs a complete wire processing cycle. It starts by automatically cutting the wire to the desired length and then precisely stripping the insulation. Depending on the configuration, it can perform single-end crimping followed by single-end housing insertion. Additionally, it offers single-end half-stripping, twisting, and tinning functionalities.

Optional features like a CCD monitor can provide visual inspection, while the crimping force monitor (CFM) ensures the accuracy and consistency of the crimping force. The machine incorporates comprehensive inspection functions to detect issues such as no wire, wire knots, missing terminals or housings, air pressure anomalies, and motor malfunctions.

With a capacity of 530-650 cycles per hour, it can process multiple wires simultaneously. For instance, it can handle 6 wires with 2 pins each or 1 wire with 8-12 pins in a single cycle. The cutting length is adjustable from 30 to 800mm, and it accommodates wires ranging from 32 to 18AWG. The rear stripping length can be set from 1 to 9mm for either half or full stripping, and the tinning length is also adjustable from 1 to 9mm. The machine operates with an air pressure of 0.5MPa.

Standard Machine Functions:

-

One side cutting, stripping, crimping, housing inserting

-

One side cutting, stripping, twisting, tinning

These functions can be selected and combined freely to suit various processing needs. Customization options are also available to cater to specific requirements. Examples of supported function combinations include:

-

One-end stripping, crimping, housing insertion; one-end stripping.

-

Two-end stripping, crimping, and housing insertion.

-

One end stripping, crimping, housing insertion; one end stripping, twisting, tinning.

-

Processing wires of the same length.

-

Processing wires of different lengths.

Applications:

This fully automatic wire processing machine is ideal for high-volume production in various industries, including:

-

Automotive electronics assembly

-

Consumer electronics manufacturing

-

Appliance manufacturing

-

Industrial automation

-

Telecommunications equipment production

-

And any other application requiring automated wire cutting, stripping, crimping with housing insertion, twisting, and tinning.

Why Choose This CE Certified Automatic Wire Processing Machine?

This CE certified machine offers a comprehensive and highly efficient solution for complex wire processing tasks. Its full automation, multi-functionality, precise controls, integrated quality inspection, and customization options significantly reduce labor costs, increase production speed, and ensure consistently high-quality results. The advanced PLC control system with remote monitoring capabilities provides unparalleled control and visibility over your production process.

Technical Specifications:

-

Model: Single-End Automatic Crimping Housing Insertion Tinning Machine

-

Power: AC220V 1300W

-

Standard Functions: Cutting, Stripping, Single-end crimping, Single-end housing insertion, Single-end half-stripping/twisting/tinning

-

Optional Functions: CCD monitor, crimping force monitor

-

Inspection Functions: No wire, Wire knotted, No terminal, No housing, Air pressure alarm, motor abnormal, etc.

-

Capacity: 530-650 times/H (can process 6 @2pin cables each time, can process 1 @8-12pin cable each time)

-

Cutting Length: 30-800mm

-

Applicable Wire: 32-18AWG

-

Rear Stripping Length: 1-9mm (half-stripping or full-stripping)

-

Tinning Length: 1-9mm

-

Air Pressure: 0.5MPa

-

Machine Dimensions: 3.81.82.2m

-

Weight: 550KG

Detailed Process Flow:

Pay-off → Pull the wire → Cut off → Strip → Twist wire → Dip tin → Crimp terminal → Crimp force monitoring (optional) → Terminal appearance CCD detection (optional) → Terminal reversal → Housing insertion → Housing pull force detection (air pressure/torque) → Finished product classification and discharge.

Advanced Control System:

This machine adopts a PLC programmable control system. The parameters of the whole machine are set digitally and can be used for file management. The modular design of the hardware part is easy and quick to replace material numbers and troubleshoot equipment. The equipment can be remotely controlled through the Internet, the production status can be monitored in real-time, and the production data can be generated and exported.

Contact Us Today for a Quote!

Optimize your wire processing with this advanced and CE certified fully automatic machine. Contact us today to learn more and request a personalized quote. Discuss your specific wire processing requirements for tailored solutions.

Keywords: Automatic Wire Crimping Housing Insertion Machine, Wire Crimping Insertion Housing Machine, Automatic Wire Crimping Insertion Housing Machine, CE Certified Wire Processing Machine, Fully Automatic Wire Processing, Wire Cutting Stripping Crimping Machine, Wire Twisting Machine, Wire Tinning Machine, CCD Monitor Wire Machine, Crimping Force Monitor, PLC Control Wire Machine.