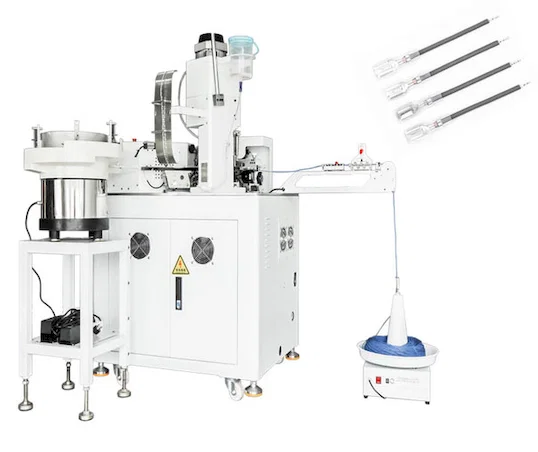

Automatic cable stripping crimping and twisting machine

This automatic crimping machine is a fully automatic cable processing machine to process wire from cutting,

Stripping, crimping, and twisting completely at once. it is suitable for processing all kinds of electric wires from

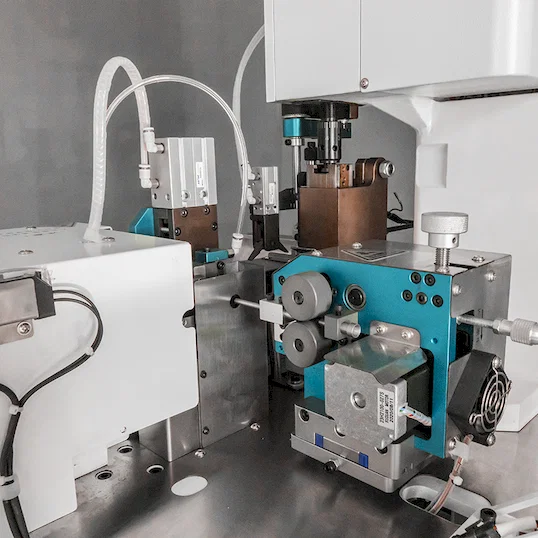

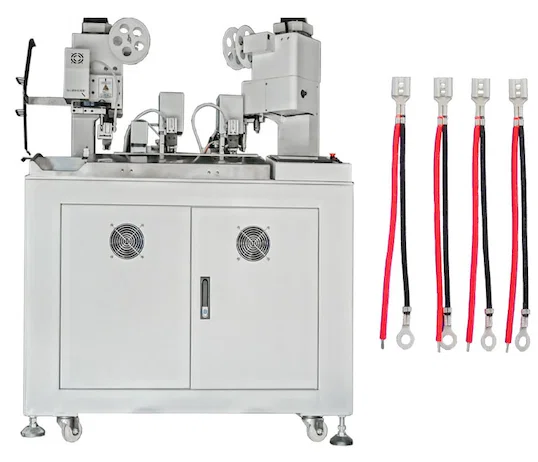

AWG14#~AWG28#(can be customized), and crimping reel-type terminals like insulated terminals or non-insulated

Terminals. the crimping die is made according to your terminals, different terminals can be pressed by this machine

Just replace the crimping die, changeover the crimping die is very quick.

Advantages:

1) from feeding cable, cutting, stripping, crimping, and twisting automatically.

2)Available wire range from AWG 14#~AWG 28# with fast speed and accuracy performance.

3)Available for crimping all kinds of chain-type terminals.

4) Changing the crimping die is very quick and convenient within 3 minutes.

5)Can be equipped with a conveyor for processing long wire.