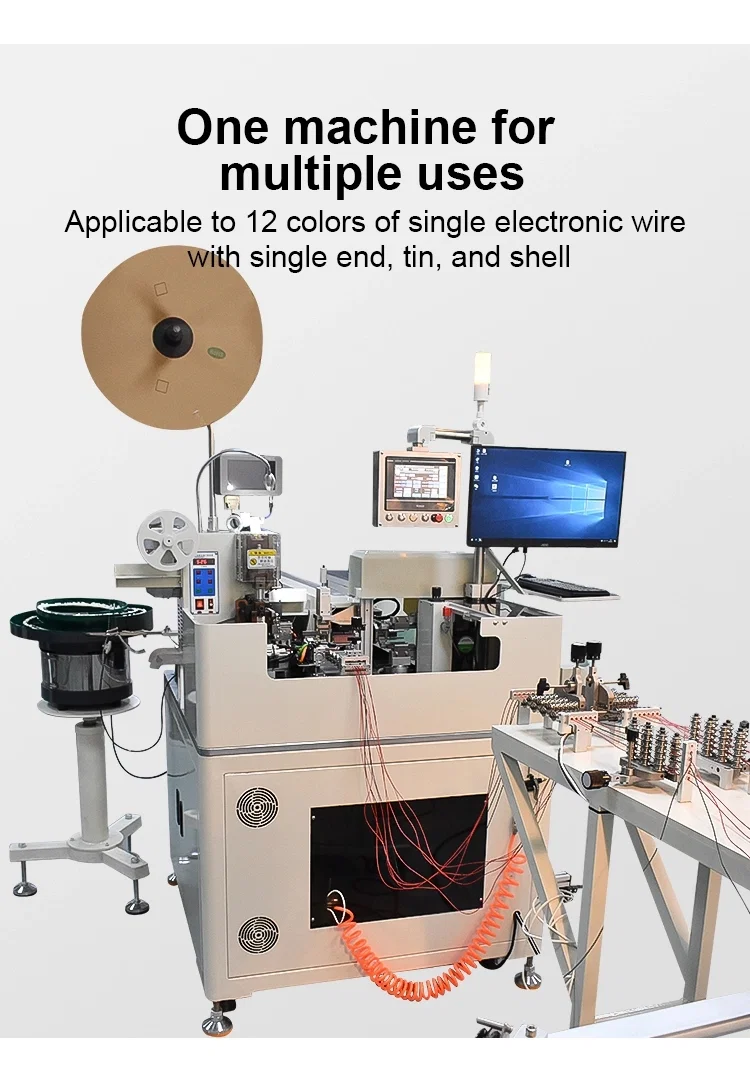

Automatic multiple wires penetrate plastic plugs shell, wire stripping position terminal crimping tinning machine, View Plastic shell inserting machine

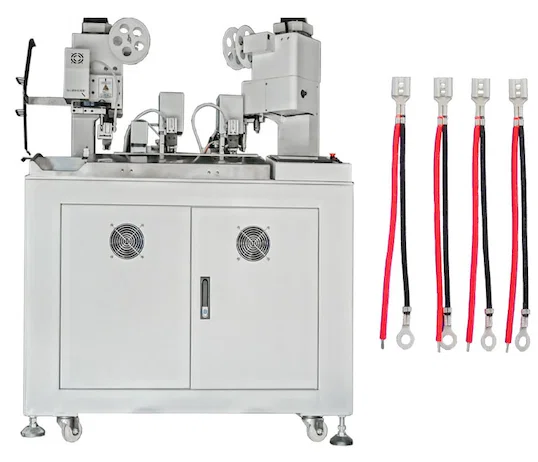

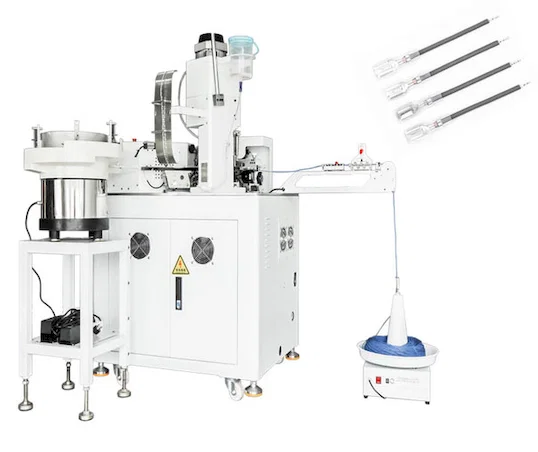

This Fully automatic multi-Position inserting machine, with wire cutting, stripping, distributing, splitting, automatic end-making, dipping, tinning, twisting, terminal, penetrating ect in a one-time function.

Applicable to 12 colors of single election wire with a single end, tin, and shelled.

No need to change the vibration plate for the same type of rubber shell 2P-12P

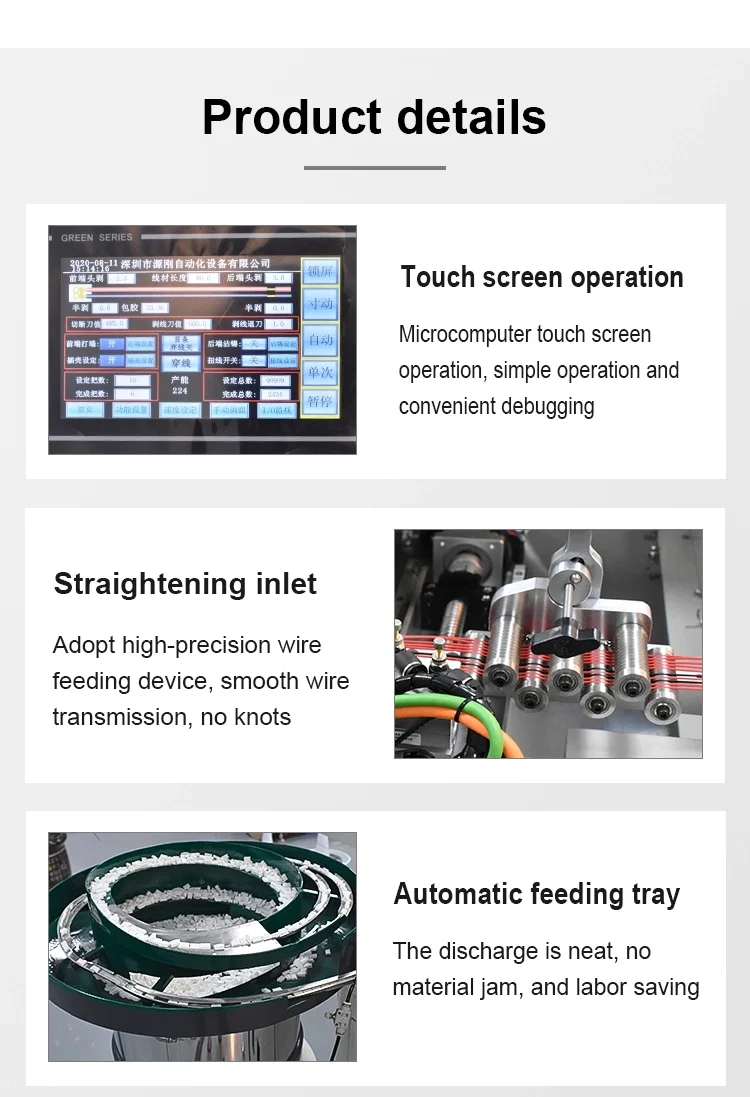

Microcomputer touch screen operation, simple operation and convenient debugging, adopt high-precision wire feeding device, smooth wire transmission, no knots, the discharge is neat, no material jam, and labor-saving

High precision ball screw and tangent accuracy can reach 0.01mm. The electrical box wiring is neat and clean, clear at a glance. Conveyor belt products are convenient and orderly.