Precision Cutting for Automotive Harness Bellows with the Advanced Corrugated Tube Cutting Machine

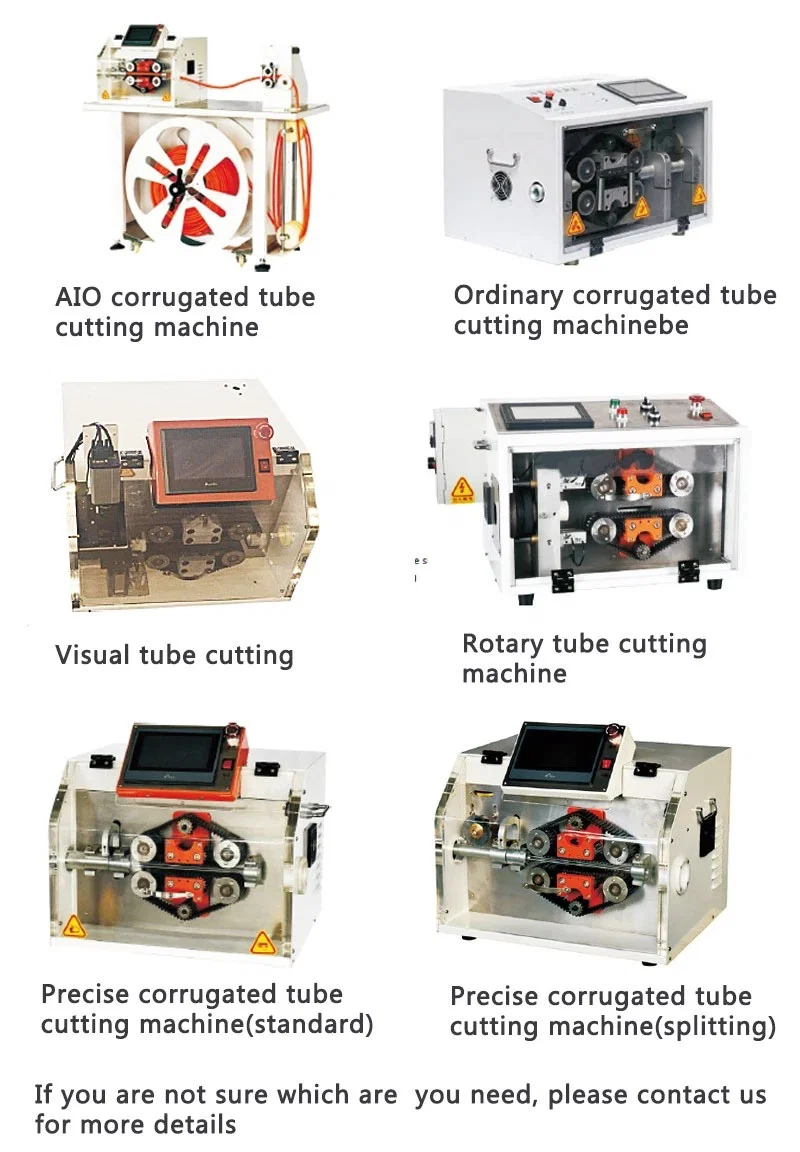

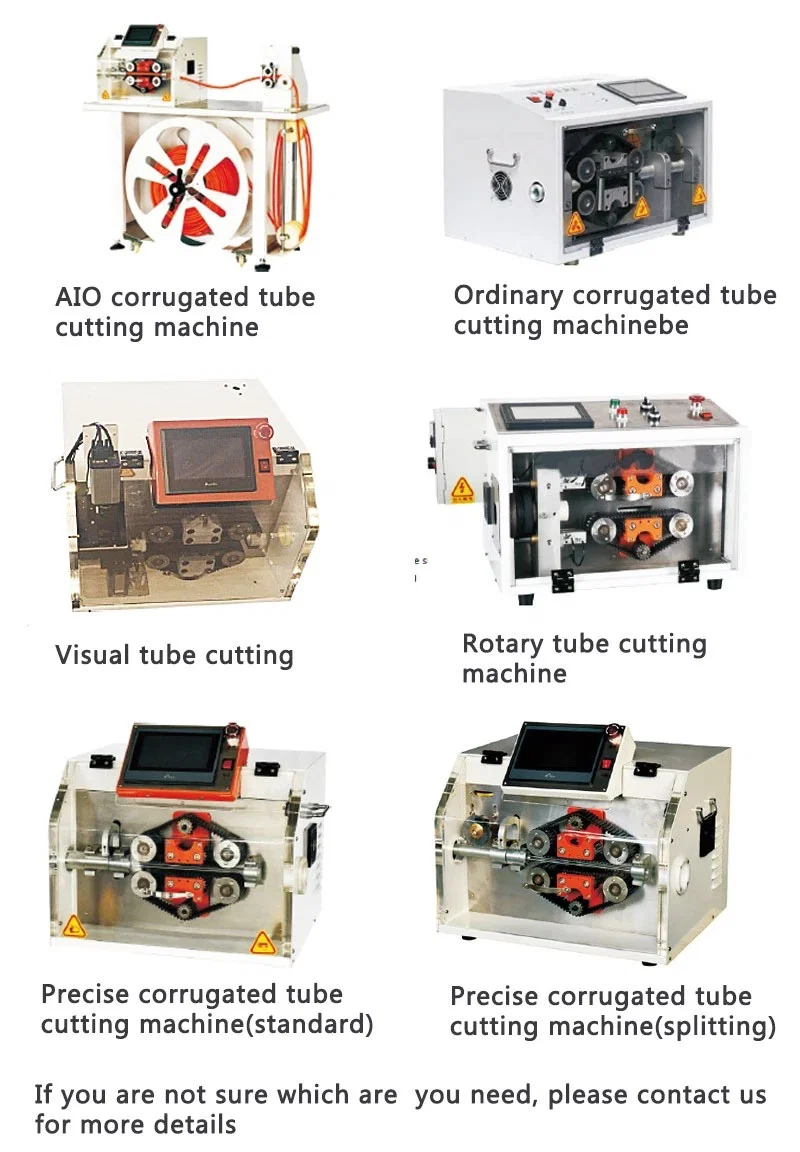

Introducing the Corrugated Tube Cutting Machine, a specialized and highly efficient solution for precise cutting of corrugated tubes and pipes. This robust Tube Cutting Machine is expertly engineered for processing bellows in automotive harnesses, but its versatility extends to cutting various round plastic pipes and bellows, including double-wall heat-shrinkable tubing. Experience superior processing efficiency, stability, and unwavering reliability with this state-of-the-art equipment.

Engineered for Automotive Harness Applications and Beyond

Specifically designed for the demanding requirements of automotive harness manufacturing, this Corrugated Tube Cutting Machine excels in cutting bellows with precision and speed. Its capabilities are not limited to automotive applications; it is equally adept at handling a broad range of round plastic pipes and bellows, making it a versatile asset for diverse industries. Whether you are working with standard corrugated tubes or double-wall heat-shrinkable tubing, this machine delivers consistently accurate and clean cuts.

Key Features and Benefits of the Corrugated Tube Cutting Machine:

- Specialized for Automotive Harness Bellows: Engineered specifically for the precise processing of automotive harness bellows.

- Versatile Cutting Capabilities: Applicable for cutting round plastic pipes, bellows, and double-wall heat-shrinkable tubing.

- High Processing Efficiency: Maximize your production output with high-speed cutting capabilities.

- Stable and Reliable Operation: Built for consistent performance and long-term reliability in demanding environments.

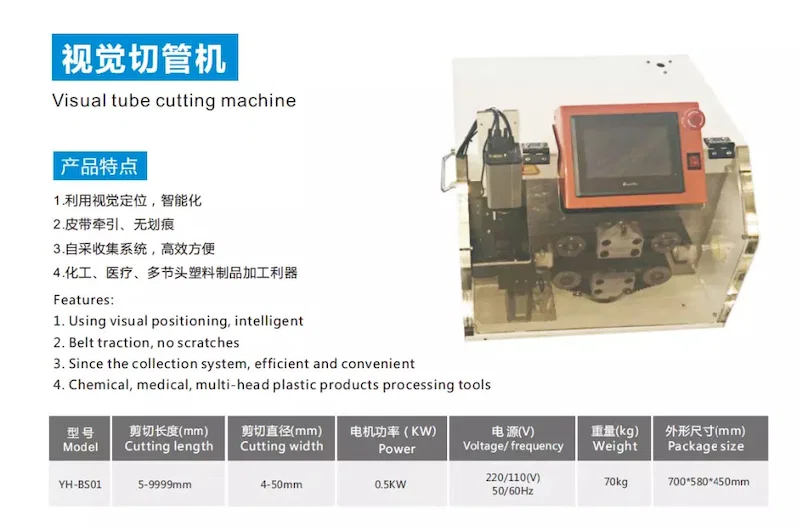

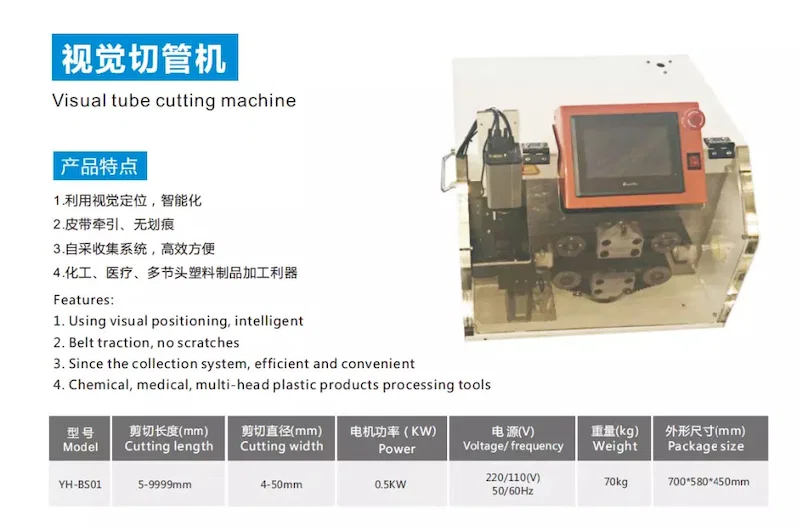

- PLC Touch Screen Control: User-friendly PLC touch screen interface for easy operation and precise control.

- Motor Cutting System: Robust motor-driven cutting for clean and accurate cuts.

- Wide Cutting Size Range: Handles tubes with outer diameters from ø5mm to ø30mm.

- Adjustable Cutting Length: Precise cutting length adjustment from 5mm to 9999mm.

- High Accuracy: Maintains cutting length accuracy within ±1%.

- Fast Cutting Speed: Achieves cutting speeds of 10-60 pieces per minute.

- Compact and Robust Design: Space-saving dimensions (580X470X500mm) and durable construction.

- Two Model Options (WPM-4.5-32-1 & WPM-4.5-32-2): Choose between standard cutting and "cut open" functionality depending on your specific application needs.

Model Specifications: Corrugated Tube Cutting Machine (WPM-4.5-32 Series)

FAQ:

1 Price terms

The price is based on EXW/FOB, if you request CFR or CIF, please give us your delivery port, and we will give you the CFR price or CIF price for reference.

2. What is your main market?

There are kinds of different clients from Asia, Africa, America, and Europe market.

3 . Could provide a professional solution based on our product?

We always promote suitable solutions based on products and satisfy clients with cost-down requirements.

4 Can we provide the sample for testing?

Yes, It will be a pleasure if u provide us with the sample for testing.

5 Do u test all goods before delivery?

Yes,100% test before shipment.

™ products are tested and guaranteed to keep in good quality with one year warranty excluding consumable parts.

If any main parts have quality problems, we will provide new parts and send them to you to change at once with detailed technical support and video illustration, or our experience engineer help to solve them. All problems and questions can be responded to within 24 hours after receiving email/phone/other chatting tools.