High-Precision Automatic Rubber and Plastic Sleeve Cutting Machine - Versatile Tube, Belt & Wire Cutter

Maximize Efficiency and Minimize Waste with Our Advanced Automatic Cutting Solution

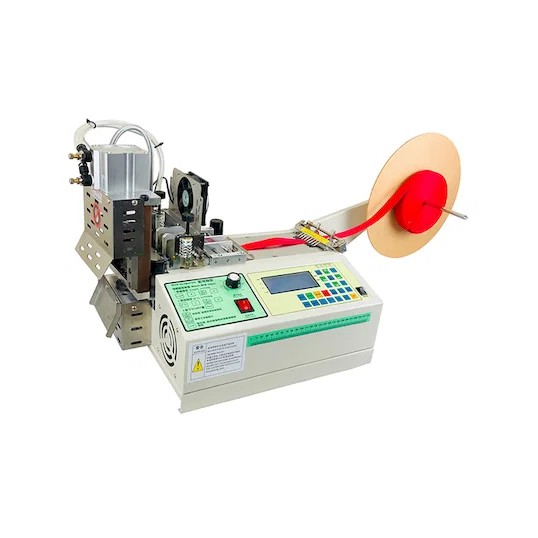

In today's competitive manufacturing landscape, precision and efficiency are crucial for success. Our Automatic Rubber and Plastic Sleeve Cutting Machine, also known as a Tube Belt Wire Cutter Machine, is expertly designed to provide accurate and high-speed cutting of a wide variety of flexible materials. Equipped with a sophisticated microcomputer numerical control device, this machine ensures consistent cutting length, exceptional precision, simple operation, and a remarkably low waste rate, making it an indispensable asset for your production line.

Engineered for Precision and Versatility

This cutting-edge machine utilizes an advanced microcomputer numerical control device that allows for precise setting of the belt cutting length. This digital control ensures consistent and accurate cuts, minimizing material waste and maximizing your output. The high level of precision achieved by this technology makes it ideal for applications where exact dimensions are critical.

Simple Operation for Enhanced Productivity

We understand the importance of user-friendly equipment. This Automatic Rubber and Plastic Sleeve Cutting Machine is designed for simple operation, requiring minimal training and allowing your operators to become productive quickly. The intuitive controls make setting cutting parameters straightforward, further enhancing efficiency and reducing the potential for errors.

Minimize Waste, Maximize Savings

The intelligent design of this machine prioritizes material conservation, resulting in a significantly low waste rate. By ensuring accurate cuts and minimizing offcuts, you can reduce material costs and improve your overall profitability.

Versatile Material Compatibility

This highly adaptable machine is suitable for cutting a diverse range of flexible materials, including:

-

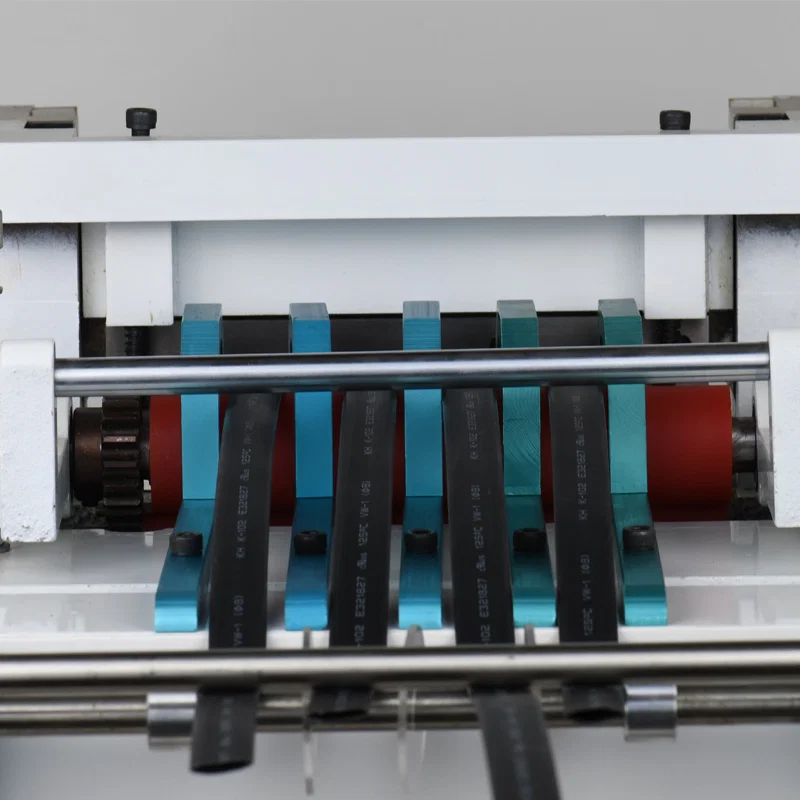

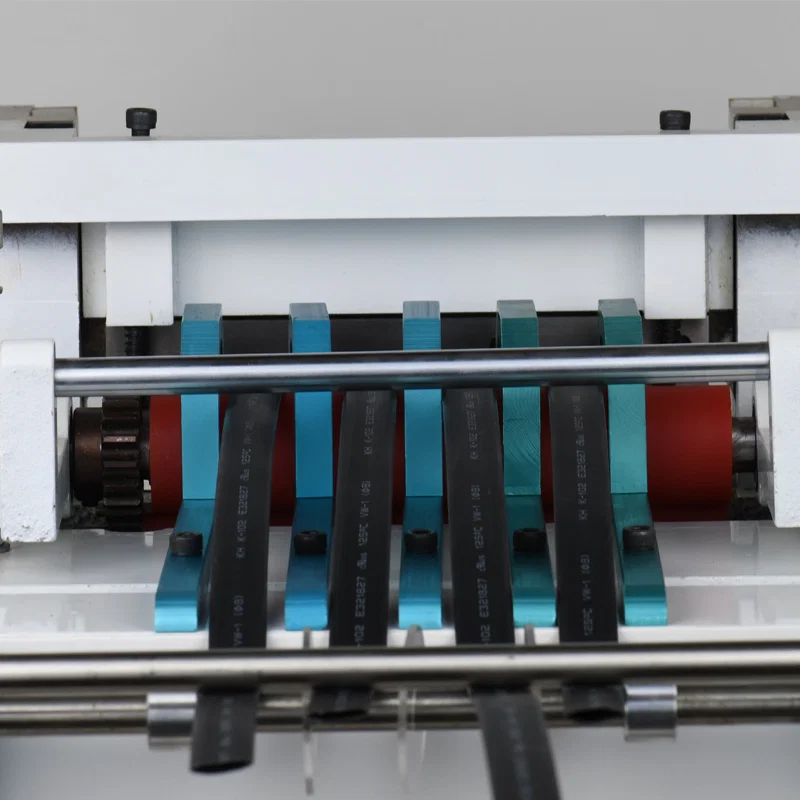

Heating shrink tubes: For precise cutting of heat shrinkable sleeves used in various electrical and electronic applications.

-

Cable wire: Ideal for cutting wires to specific lengths for wiring harnesses and other assemblies.

-

PVC tubes: Efficiently cuts PVC tubing for various industrial and commercial uses.

-

Insulating paper: Provides accurate cutting of insulation paper for electrical insulation purposes.

-

Twin surface tape: Precisely cuts double-sided adhesive tapes for bonding and mounting applications.

-

Bonding tape: Suitable for cutting various types of adhesive bonding tapes to desired lengths.

-

Cotton belts: Accurately cuts cotton webbing and belts for textile and industrial applications.

-

Zippers: Enables precise cutting of zippers for garment and accessory manufacturing.

-

And many other similar flexible materials.

Key Features and Benefits at a Glance:

-

Automatic Operation: High-speed and efficient cutting with minimal manual intervention.

-

Microcomputer Numerical Control: Ensures precise and consistent cutting lengths.

-

User-Friendly Interface: Simple and intuitive controls for easy operation.

-

Low Waste Rate: Maximizes material utilization and reduces costs.

-

Wide Material Compatibility: Handles heating shrink tubes, cable wire, PVC tubes, insulating paper, tapes, belts, zippers, and more.

-

High Precision Cutting: Delivers accurate cuts for demanding applications.

-

Durable Construction: Built for long-lasting performance in industrial environments.

-

Versatile Sizing Cutting: Ideal for cutting materials to specific dimensions.

Ideal Applications:

-

Electronics manufacturing

-

Automotive wiring harness production

-

Appliance manufacturing

-

Textile and garment industry

-

Packaging and labeling

-

Industrial assembly

-

DIY and crafting applications

Why Choose Our Automatic Rubber and Plastic Sleeve Cutting Machine?

Our Automatic Rubber and Plastic Sleeve Cutting Machine offers a powerful combination of precision, efficiency, versatility, and ease of use. Its advanced features and robust construction make it an invaluable asset for businesses looking to streamline their cutting processes, minimize waste, and achieve consistent, high-quality results across a wide range of flexible materials.

Contact us today to learn more about how our Automatic Rubber and Plastic Sleeve Cutting Machine can optimize your production line and contribute to your business success.

|

Model

|

WPM-100

|

WPM-160

|

WPM-300

|

|

Voltage

|

100V 220V

|

100V 220V

|

100V 220V

|

|

Power

|

1/4HP

|

1/6HP

|

1/8HP

|

|

Tolerance

|

1-100mm

|

1-160mm

|

1-300mm

|

|

Cut length

|

0.1-9999.9mm

|

0.1-9999.9mm

|

0.1-9999.9mm

|

|

Weight

|

34 kgs

|

48 kgs

|

55 kgs

|

|

Size

|

400 x 370 x

340mm

|

600 x 700 x

1000mm

|

800 x 900 x

1500mm

|