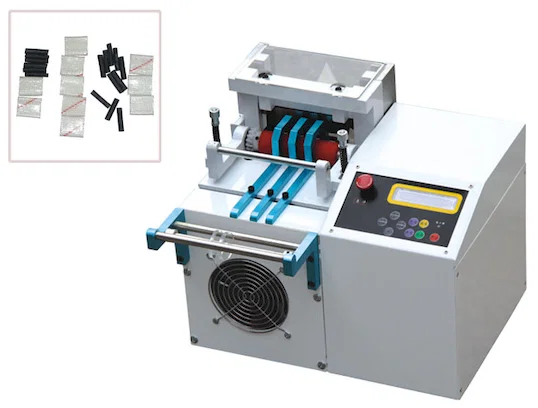

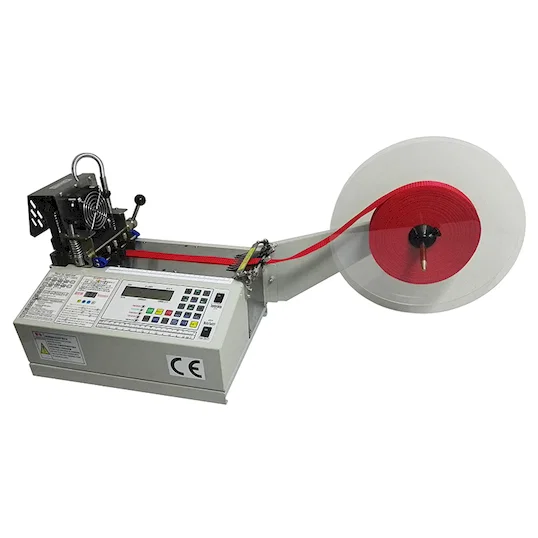

Auto BOPP Tape Cutting Machine

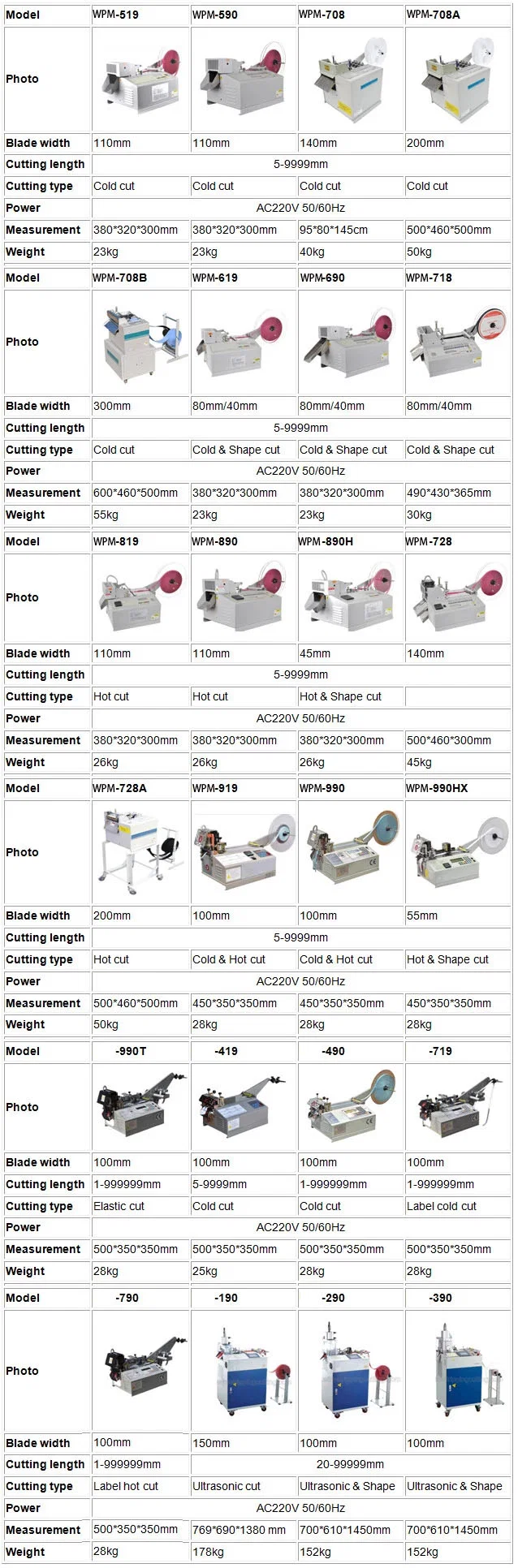

Specifications

Adhesive Tape Cutting Machine, Double Sided Tape Cutting Machine, Bopp Tape Cutting MachineAvailable Tape Width:5~100mmAvailable Cutting Length:1~999999mmTape Cutting Speed:100~120Pcs/MinCutting Tolerance: ≤0.5mmCutting Type: Hot & Cold knives, Straight cutKnife Temperature: Max 400 degrees, AdjustablePower Supply: AC220V/110V 50/60Hz,600WAvailable Materials: Fabric, satin, webbing tapes, elastic tapes, and belts,Nylon zipper, leather, Hook & Loop, tubes, etc- Inquiry now