Comprehensive Terminal Machine Blades and Tooling for Automatic Crimping

Our extensive range of terminal machine blade options and tooling caters to various needs in automatic terminal crimping. We offer Various types of automatic terminal crimping machine tools, including die mute OTP die blade solutions, ensuring precision and efficiency in your wire termination processes.

We provide a wide array of terminal machine mold accessories, encompassing cold press terminal knife mold components and otp terminal mold cutter designs. Our inventory also includes standard and custom automatic terminal machine blade options to perfectly match your specific requirements.

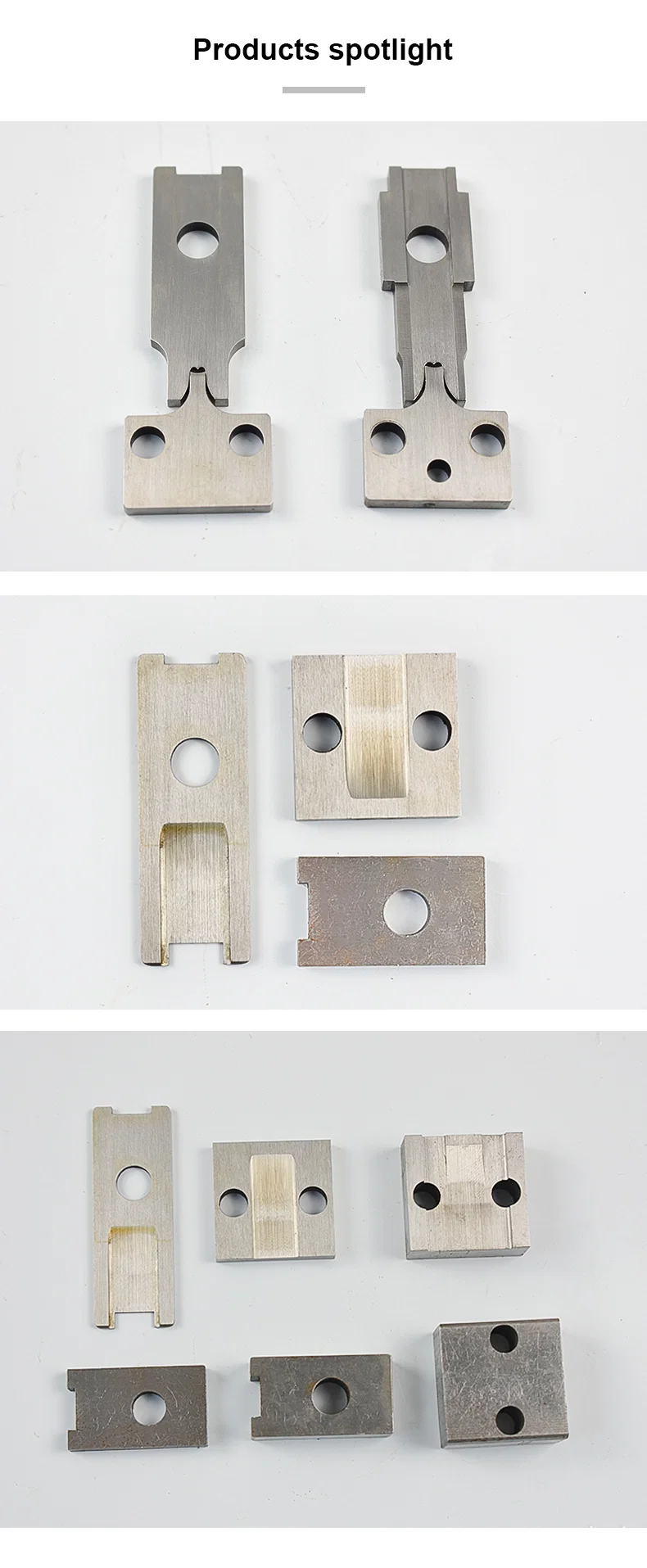

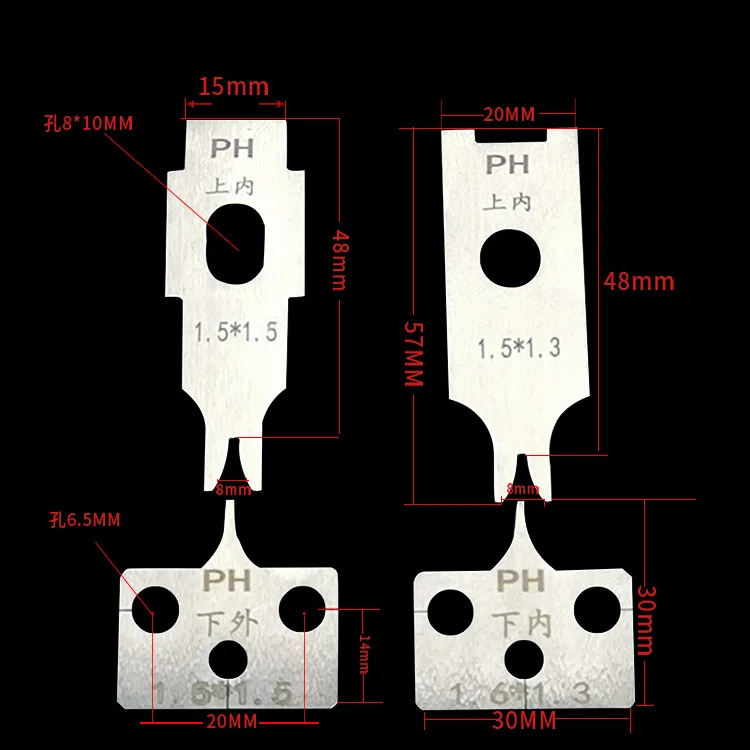

Automatic Terminal Crimping Machine Blades - A Complete Set:

A standard set of our Automatic terminal crimping machine blades typically includes the following precision components:

-

Upper outer cut

-

On the inside cut

-

Under the outer cut

-

Under the inside cut

-

Upper cutter

-

Under the cutter

-

Under the inside cut (repeated for thoroughness)

-

Cushion1

-

Cushion2

Uncompromising Material Quality:

We prioritize the quality and longevity of our tooling. Our blades are crafted from carefully selected high-quality DC53 steel. Each piece of steel undergoes strict testing before processing to ensure optimal performance and durability. We utilize a US Niton spectrometer to precisely detect and verify the material composition, guaranteeing the integrity of our blades.

Key Functions of Our Blades:

-

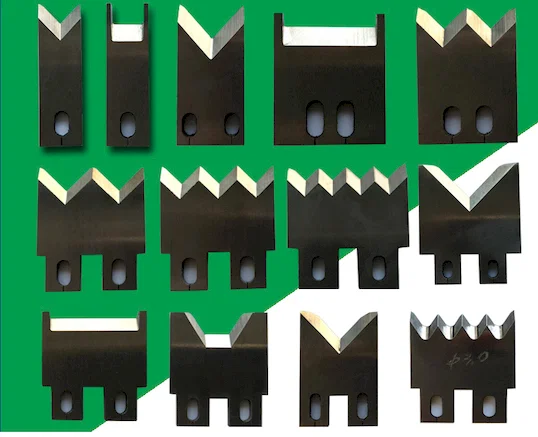

Cutting knife Function: Designed to precisely cut the end of the cable, ensuring a flat and even surface for optimal crimping.

-

Peeling knife Function: Engineered for efficient and clean wire peeling, as well as precise wire cutting to the desired length.

Customization Options:

We understand that different terminals and applications require specific tooling. Therefore, we offer custom manufacturing of our automatic terminal machine blades and other tooling components. Our experienced team can design and produce blades and molds tailored to your unique specifications.

Key Features and Benefits:

-

Comprehensive Range: A wide selection of terminal machine blades and tooling for various applications.

-

High-Quality DC53 Steel: Ensures exceptional durability and wear resistance.

-

Rigorous Material Testing: Guarantees consistent quality and performance.

-

Precision Manufacturing: Delivers accurate and reliable crimping results.

-

Customization Available: Tailor-made solutions to meet your specific needs.

-

Essential Functions: Includes blades for cutting and peeling wires effectively.

Why Choose Our Terminal Machine Blades and Tooling?

Our commitment to quality materials, precision manufacturing, and comprehensive tooling options makes us your ideal partner for automatic terminal crimping. We provide durable and reliable blades designed to enhance the efficiency and accuracy of your wire termination processes.

Contact Us Today for Your Terminal Machine Tooling Needs!

Whether you require standard blades, specialized OTP die blades, or custom tooling solutions, our team is ready to assist you. Contact us today to discuss your specific requirements and request a personalized quote.

Keywords: terminal machine blade, Various types of automatic terminal crimping machine tools, die mute OTP die blade, terminal machine mold accessories, cold press terminal knife mold, otp terminal mold cutter, automatic terminal machine blade, custom, Automatic terminal crimping machine blades, upper outer cut, On the inside cut, under the outer cut, under the inside cut, upper cutter, under the cutter, under the inside cut, cushion1, cushion2, DC53 steel, US Niton spectrometer, Cutting knife Function, Peeling knife Function.