OTP Tungsten Steel Crimping Blade

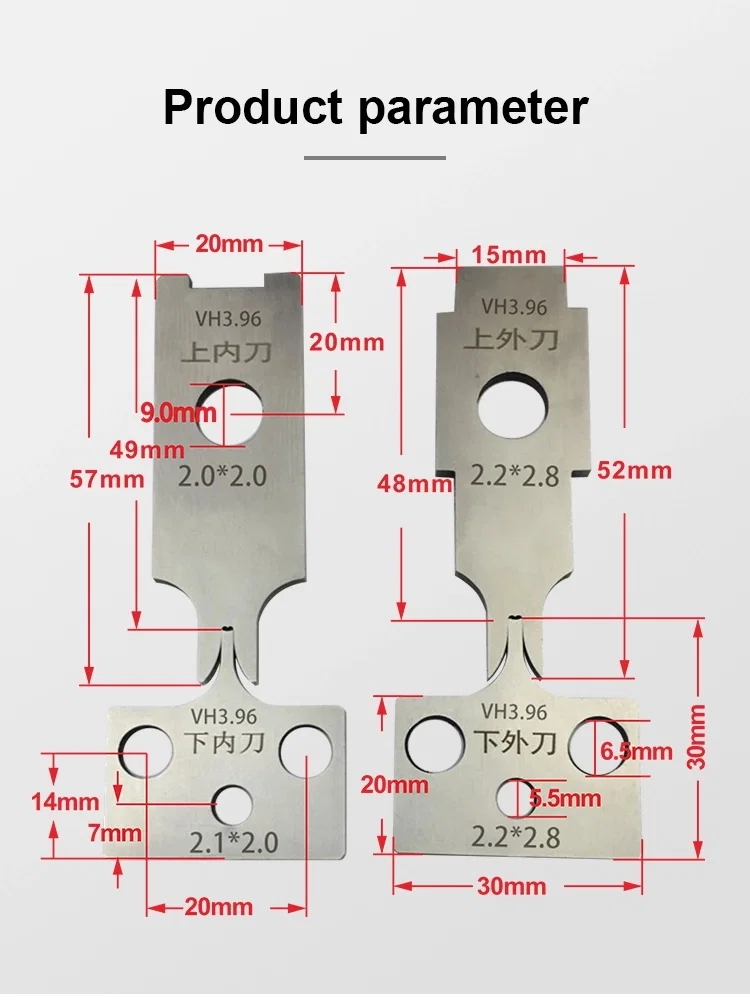

Specifications

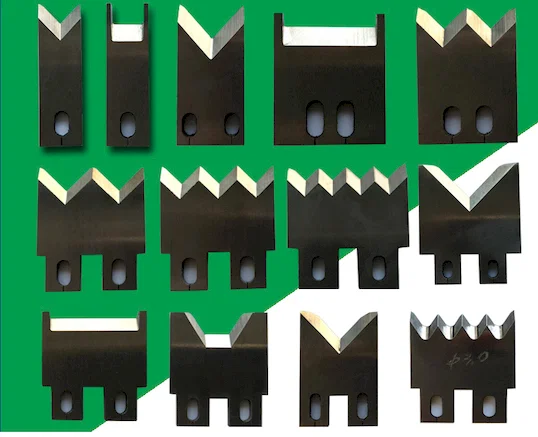

Tungsten steel blade, OTP moldsBlade,Terminal machine blade, OTP blade, Wire Strip And Crimp Machine Dies, Assembly Knife For Crimp Machine, Crimping Knife, Precision Blade for wire stripping machine cable cutting machine, Otp Blade, Stripper Blade, Wire Cutting Machine Blade- Inquiry now