Boost Assembly Efficiency with the Non-Standard Customization Deep Hole Bracket Locking Screwdriver Machine

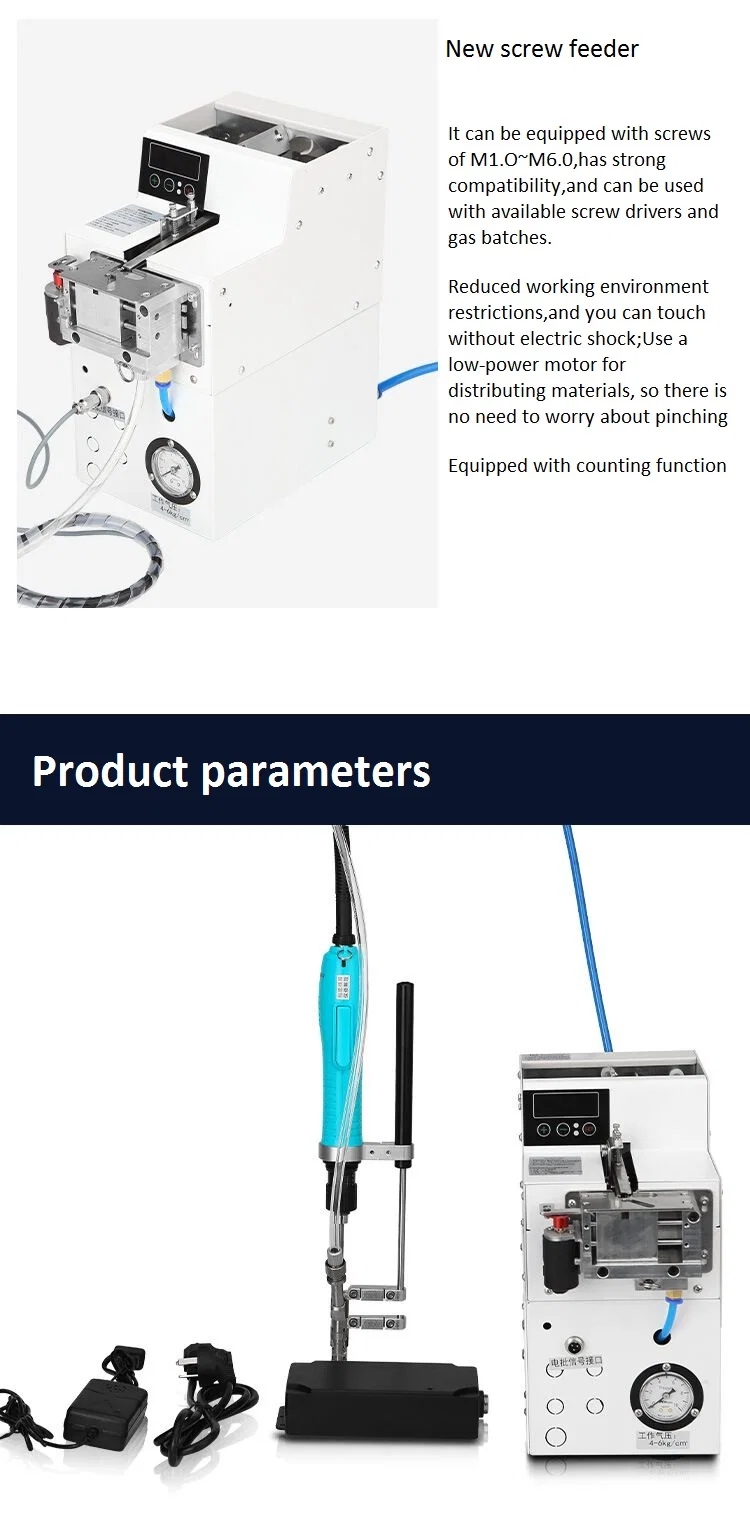

Introducing the Non-standard customization deep hole bracket air blowing screw feeder Handheld automatic locking screwdriver machine, a revolutionary solution designed to dramatically improve your assembly processes. This versatile machine, also known as a Handheld Automatic Screw Locking Machine or Pneumatic Feeding System Automatic Handheld Screw Locking Machine, integrates a Screw Feeder Machine with a handheld screwdriver for unparalleled efficiency and ease of use. Experience significant improvements in production speed, reduced labor costs, and enhanced ergonomics with this cutting-edge locking screwdriver machine.

Maximize Productivity and Minimize Labor Costs

The core benefit of this locking screwdriver machine is its ability to improve production efficiency, reduce labor, and save cost. By automating the screw feeding process, it eliminates the need for operators to manually pick and place screws. The Screw Feeder Machine automatically delivers screws directly to the driver tip, drastically speeding up assembly times and freeing up operators for other tasks.

Ergonomic Design for Effortless One-Handed Operation

Designed with operator comfort in mind, this Handheld Automatic Screw Locking Machine allows for one-hand assembly. Operators can easily lower the lightweight piezoelectric screwdriver to complete screw locking effortlessly. This ergonomic design significantly reduces worker labor intensity and fatigue, leading to improved job satisfaction and reduced errors.

High-Speed Performance and Clean Screw Handling

Experience exceptional speed and precision. This machine achieves an efficiency as high as 70 screws per minute, significantly outpacing manual assembly. Furthermore, because the operator does not take the screw by hand, the screw will not be polluted again, maintaining cleanliness and product quality.

Versatile Features and Optional Configurations

The Pneumatic Feeding System Automatic Handheld Screw Locking Machine is not just efficient, but also intelligent. It can be used for building calculations and alarms, providing valuable data and feedback for production monitoring. Optional configurations are also available to further customize the machine to specific needs.

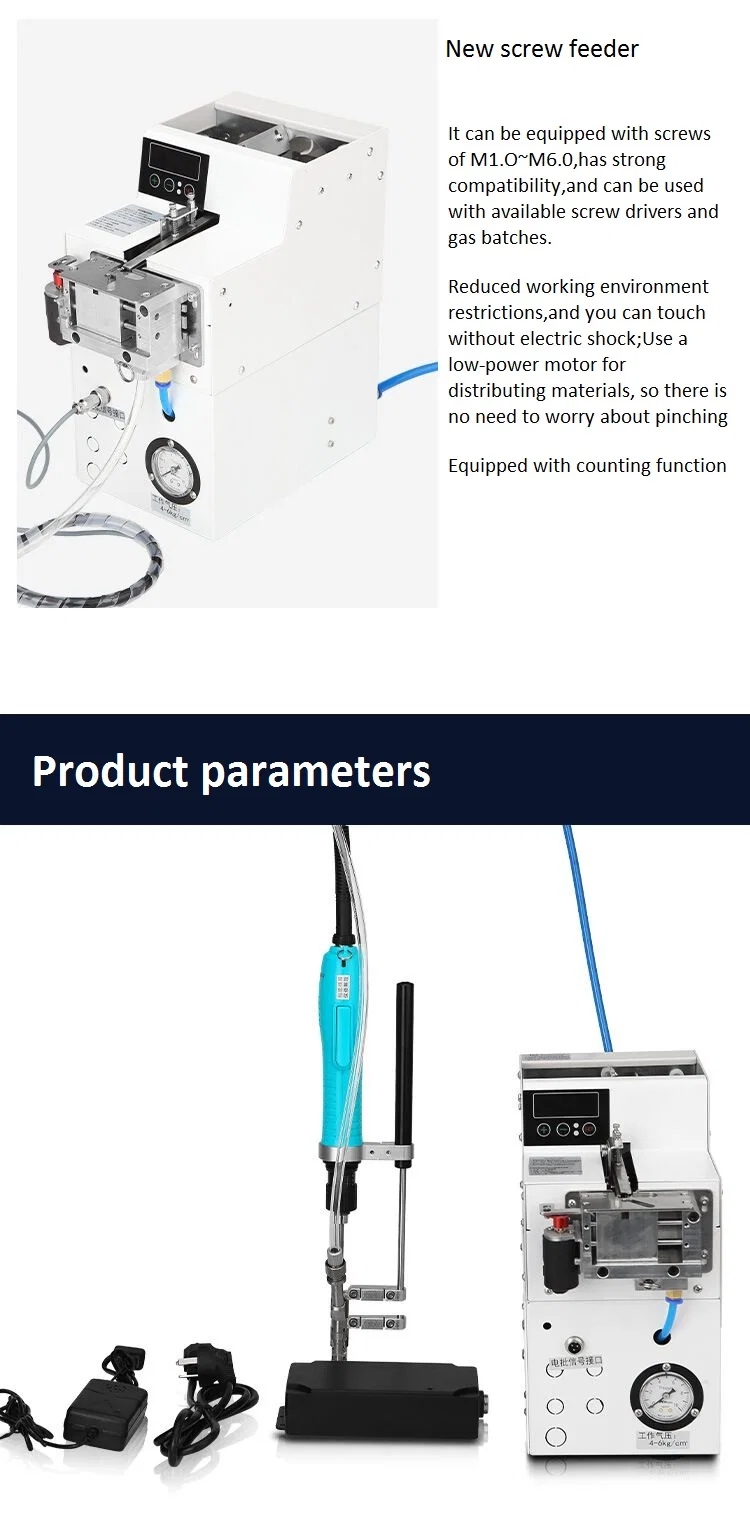

Important Limitation and Electric Screwdriver Data

To ensure optimal performance, screws and screw products must meet a specific condition: the ratio of screw head diameter (d) to screw thread length (L) should be L ≥ d * 1.2 (screw rod length must be greater than 1.2 times the screw cap diameter).

Electric Screwdriver Data:

- Torque: Adjustable

- Rotational Speed: 0-1800 RPM

- Applicable Screws: M1.0-M6.0

- Applicable Screw Length: 2.7-25mm

- Applicable Nut Diameter: 1.0-12mm

- Screw Material & Type: No limit, but total screw length > 1.2 times nut diameter.

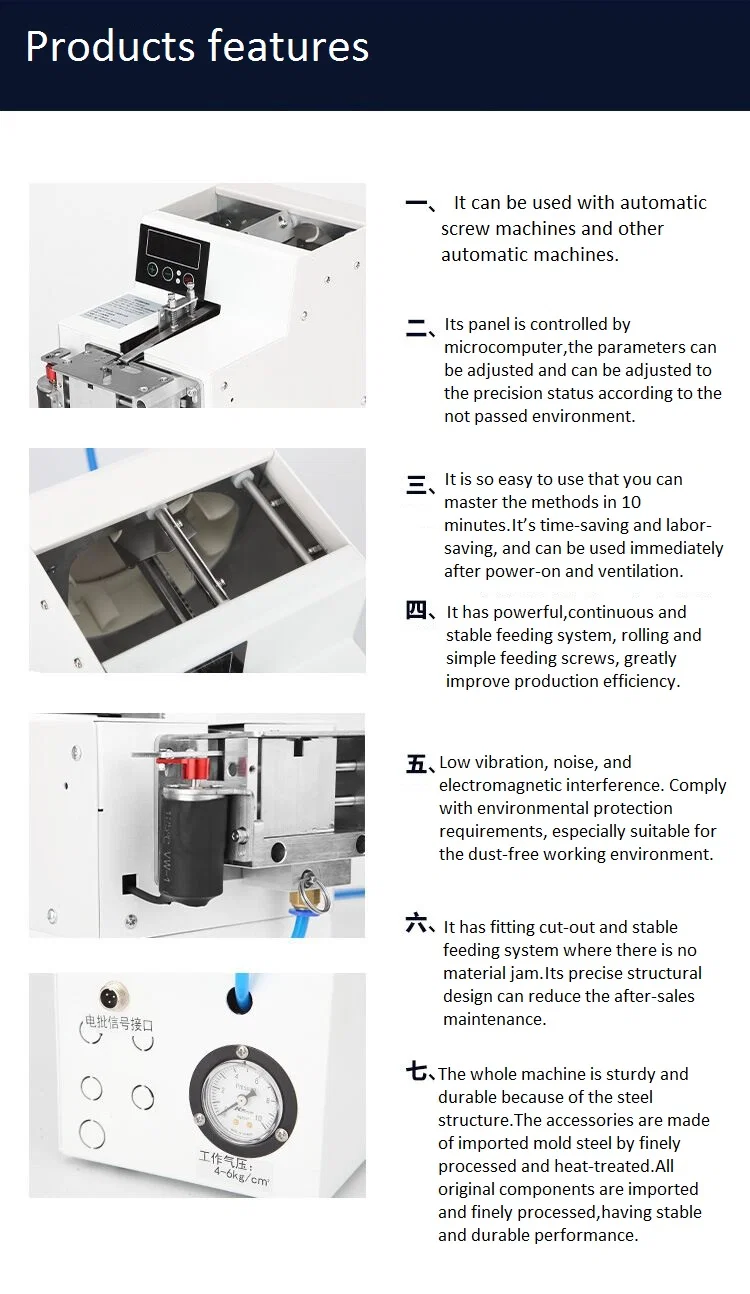

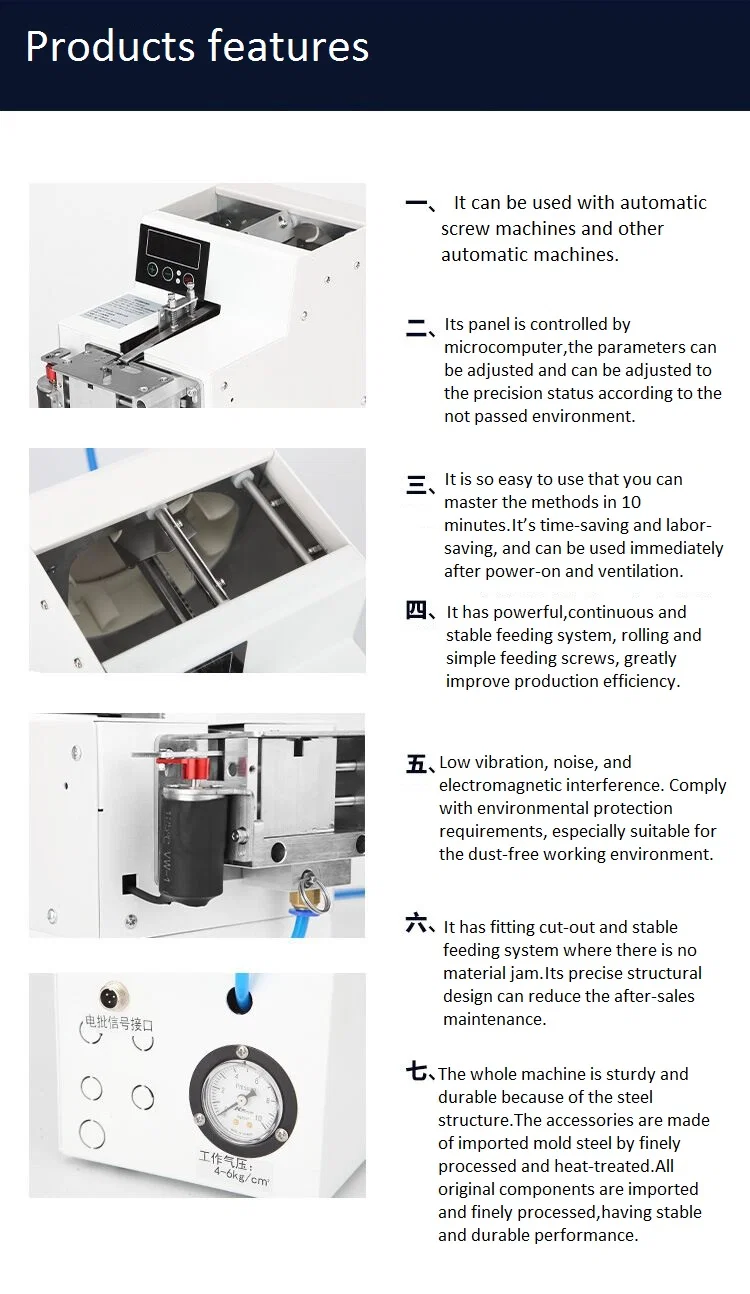

Key Features and Benefits of the Non-Standard Customization Locking Screwdriver Machine:

- Non-Standard Customization: Deep hole bracket and air blowing screw feeder for specialized applications.

- Automatic Screw Feeding: Eliminates manual screw handling, boosting efficiency and speed.

- One-Handed Operation: Ergonomic design reduces operator fatigue and simplifies assembly.

- High-Speed Assembly: Achieves speeds up to 70 screws per minute.

- Clean Screw Handling: Prevents screw contamination for improved product quality.

- Reduced Labor Intensity: Minimizes physical strain on operators.

- Building Calculations & Alarms: Intelligent features for production monitoring (optional).

- Versatile Applications: Suitable for a wide range of screw sizes and materials (within specifications).

Optimize Your Screw Locking Process Today!

The Non-standard customization deep hole bracket air blowing screw feeder Handheld automatic locking screwdriver machine is the ideal locking screwdriver machine for manufacturers seeking to drastically improve their assembly efficiency, reduce labor costs, and enhance ergonomics. Its advanced features and user-friendly design make it an invaluable asset for any production line. Contact us today to learn more about how this Handheld Automatic Screw Locking Machine can transform your screw locking operations and elevate your productivity!