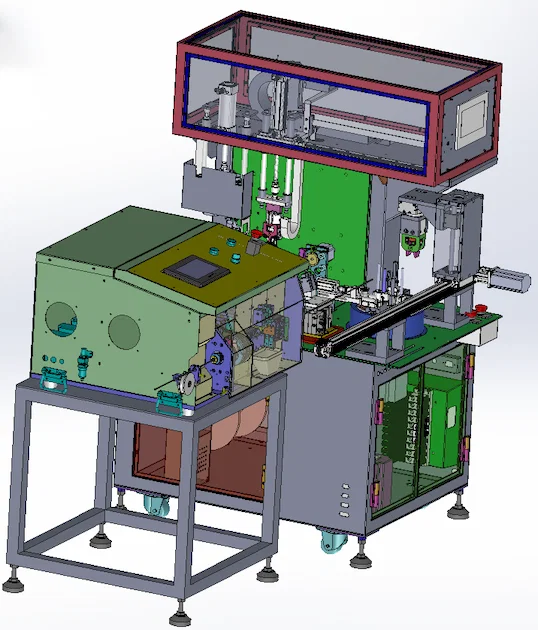

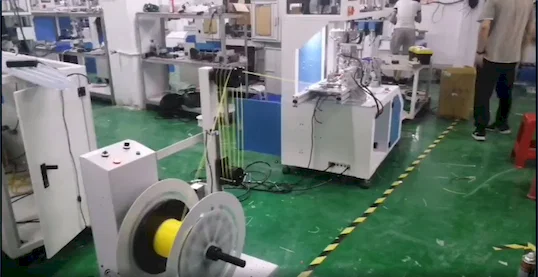

Hose Cut Coil Twist Tie Machine WPM-HCCT

Model No: WPM-HCCT

Specifications

Hose cutting Coiling twist tie machine WPM-HCCT, Hose Cutting Crimping And Winding Twist Tie Machine, Electric Wire Harness Binding Machine, Cable Wire Coil Winding MachineWinding distance: 70-180mm (line) /140-220mm (pipe)Applicable wire: USB/DC/2 tube /3.Cutting line precision:60mm.Tie Diameter:< 50mm.Head length: 40-130mmSuitable for the belt: rubber core.Length of cut: 3-30mWinding appearance: circle double-type.Theoretical output: no more than 700PCS/H- Inquiry now