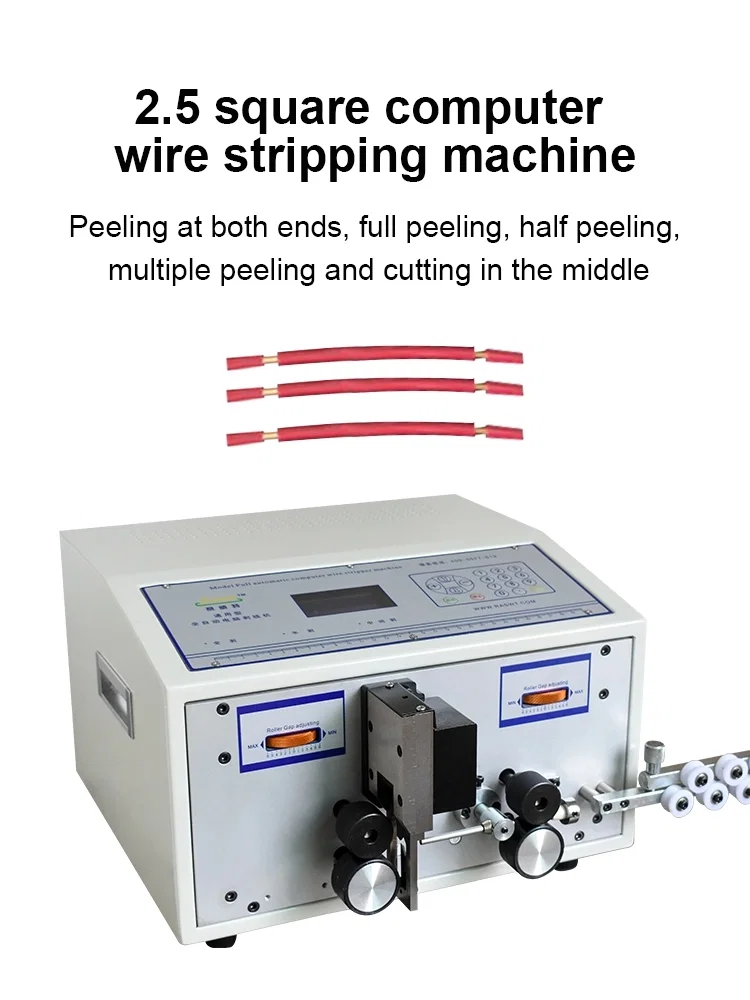

High-speed automatic computer stripping machine, wire stripper, stripping wire machine

The machine uses the latest 32 intelligent control system, Chinese and English switching liquid crystal display, and can store hundreds of pieces of information, called at any time, fast efficiency.

Compatible with the general features of 330# wire cutting machine. Double linear, two wires can be processed simultaneously, not only saving labor and time but also improving productivity.

Mainly used for electronic wire, silicone wire, Teflon wire, glass fiber of cotton, isolated lines, coaxial, and trunking. Automatic cutting, stripping, semi-stripping, multi-segment stripping, and twisting functions once completed, can instantly transform wire specifications and dimensions, it’s very economic.

The machine is mainly used in electronics, electrical appliances, toys, auto parts, and other industries.